on the larger wheel. If the depth that each grain cuts into

the workpiece remains the same, the grain on the

smaller wheel will remove a smaller volume

(volume = length width depth) of material in the

same time as the grain on the larger wheel. However,

for both grains to provide the same cutting action, they

both have to remove the same volume of material in the

same length of time. To make the volume of material

the grain on the smaller wheel removes equal to that of

the grain on the larger wheel, you have to either make

the grain on the smaller wheel cut deeper into the

workpiece or cover a larger workpiece surface area at

its original depth of cut.

To make the grain cut deeper, you must increase the

feed pressure on the grain. This increase of feed

pressure will cause the grain to be torn from the wheel

sooner, making the wheel act like a softer wheel. Thus,

the grain depth of cut theory says that as a grinding

wheel gets smaller, it will cut like a softer wheel because

of the increase in feed pressure required to maintain its

cutting action.

The opposite is true if the wheel diameter increases.

For example, if you replace a wheel that is too small

with a larger wheel, you must decrease feed pressure to

maintain the same cutting action.

The other previously mentioned way to make a

grain on a smaller wheel remove the same amount of

material as a grain on a larger wheel is to keep the depth

of cut the same (no increase in feed pressure) while you

increase the surface area the grain contacts. Increasing

the surface area requires lengthening the contact area,

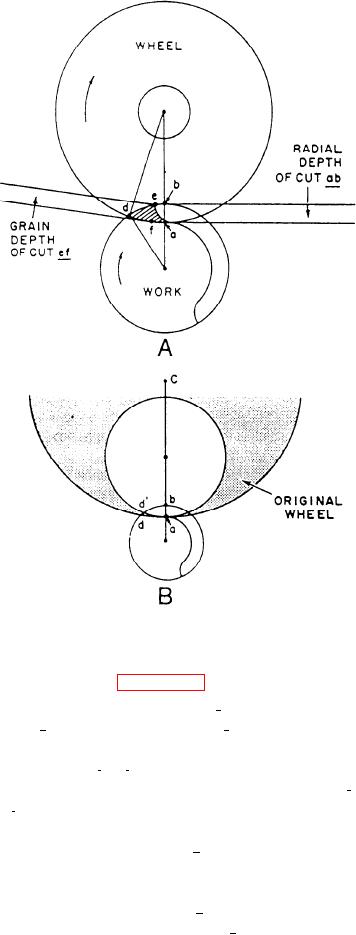

Figure 10-1.--Grain depth of cut; center-type machine.

since the width remains the same. To lengthen the

contact area, you can either speed up the workpiece

rotation or slow down the wheel rotation. Either of these

actions will cause a longer surface strip of the workpiece

grinding wheel and a workpiece; ab is the radial depth

to come in contact with the grain on the wheel, thereby

of cut, ad is the arc of contact, and ef is the grain depth

increasing the volume of material removed.

of cut. As the wheel rotates, the grain moves from the

point of contact a to d in a given amount of time. During

As mentioned earlier, the opposite is true if you

the same time, a point on the workpiece rotates from d

increase the wheel diameter. To keep from removing a

to e, at a slower speed than that of the wheel. During

larger volume of material, you must decrease the

surface of the workpiece with which the grain comes

this time the grain will remove an amount of material

into contact. You can do this by either slowing down

represented by the shaded area ade. Now refer to view B

the workpiece rotation or speeding up the wheel

and assume that the wheel has worn down to a much

rotation.

smaller size, while the wheel and work speeds remain

unchanged. The arc of contact ad' of the smaller wheel

Keep in mind that all of these actions are based on

is shorter than the arc of contact ad of the original

the grain depth of cut theory. That is, making

(larger) wheel. Since the width of the grains remains the

adjustments to the grinding procedure to make one

same, decreasing the length of the arc of contact will

wheel cut like another. The following summary shows

decrease the surface (area = length width) that a grain

the actions you can take to make a wheel act a certain

on the smaller wheel covers in the same time as a grain

way:

10-2