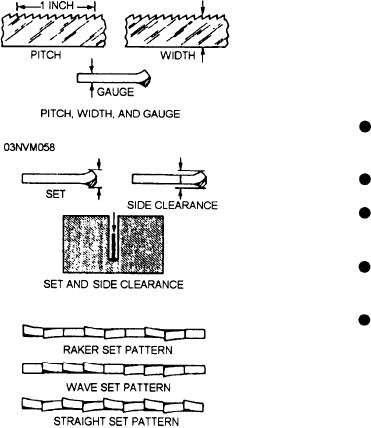

GAUGE: The thickness of a blade. This measure-

Good results from the use of any metal-cutting

bandsaw depends upon the careful choice of a blade.

ment is expressed in thousandths of an inch. Saw

Tooth pitch should be considered in relation to the

bands come in three gauges--0.025, 0.032, and 0.035

hardness and toughness of the material being worked,

inch.

and the thickness of the workpiece. At least two teeth

SET: The bend or spread given to the teeth to

should be in contact with the work at all times during

provide clearance for the body of the blade when you

the cutting operation. When you cut thick material,

make a cut.

select a tooth pitch that allows the smallest possible

number of teeth to be in contact with the material.

SIDE CLEARANCE: The difference between the

More teeth in contact means that a greater feed

dimension of the gauge of the blade and the set of the

pressure is required to force them into the material.

teeth. Side clearance provides running room for the

Excessive feed pressure will cause the cut to be off the

body of the blade in the kerf or cut. Without side

mark.

clearance, the saw band will bind in the kerf.

SET PATTERN: One of three distinct patterns

Saw Bands

(raker, wave, and straight) in which teeth are set. The

raker set pattern is used to cut solid cross-section

A saw band has the following characteristics,

work. The wave set pattern is used to cut hollow

which are illustrated in figure 5-58.

materials, such as pipes and tubing. The straight set

pattern is not used to any great extent to cut metal.

PITCH: The number of teeth per linear inch. Every

saw blade has a specific even number of teeth per

TEMPER: The degree of hardness of the teeth,

linear inch. Normally this is from 6 to 32 teeth per inch

indicated by the letters A and B, with temper A being

of blade.

the harder. The A or B designation will only be found

on the container the blade was shipped in. Temper A

WIDTH: The distance across the flat surface of the

saw blades are used for practically all bandsaw

saw band (back to the tip of the tooth). The width

metal-cutting work.

measurement is always expressed in inches or

fractions of an inch. Blades are available in widths up

to 1 inch.

GRINDERS

Grinders are simple machines that allow you to

reshape, form, and sharpen metal-cutting tools, or

other tools. The type of grinder discussed in this

chapter is the pedestal grinder.

The main parts of a pedestal grinder are as follows:

A motor with an extended shaft for mounting

grinding wheels.

A mounting base for the motor.

An adjustable tool rest for steadying the work

piece for grinding.

Wheel guards mounted over the grinding

wheel as a safety feature.

A shield fastened to the wheel guards to pro-

tect the operator from flying chips

The pedestal grinder is one of the most common and

versatile machine found in most shops. You will prob-

ably use this piece of equipment more than any other

piece of equipment found in your shop. You will use it

to clean welds, remove burrs, sharpen tools, dress up

Figure 5-58.--Saw band characteristics.

5-33