particular job is determined by the size and material

uses are presented later in this chapter to help you

composition of the section and the material to be cut.

understand the differences in blades.

Use coarse pitch teeth for wide, heavy sections to

POWER HACKSAWS

provide ample chip clearance. For thinner sections,

use a blade with a pitch that will keep two or more

The power hacksaw (fig. 5-53) is found in all

teeth in contact with the work so that the teeth will not

except the smallest shops. It is used to cut bar stock,

straddle the work and strip the teeth. In general, you

pipe, tubing, or other metal stock. It consists of a base,

should select blades according to the following

a mechanism for causing the saw frame to reciprocate,

information:

and a clamping vise for holding the stock while it is

being sawed. There are two types of power hacksaws:

Coarse (4 teeth per inch) for soft steel, cast

the direct mechanical drive and the hydraulic drive.

iron, and bronze

The power hacksaw shown in figure 5-53 has a

Regular (6 to 8 teeth per inch) for annealed

capacity of 4" 4". This means it can handle material

high-carbon steel and high-speed steel

up to 4 inches wide and 4 inches high.

Medium (10 teeth per inch) for solid brass

A power hacksaw will have one of three typos of

stock, iron pipe, and heavy tubing

feed mechanisms:

Fine (14 teeth per inch) for thin tubing and

Mechanical feed, which ranges from 0.001 to

sheet metals

0.025 inch per stroke, depending upon the

class and type of material being cut

speeds

Hydraulic feed, which normally exerts a con-

Speed for hacksaws is stated in strokes-per-minute,

stant pressure, but is designed so that the feed

counting only those strokes that cause the blade to make

stops automatically at hard spots to decrease

a cut on the stock are counted. A gear shift lever is used

the pressure on the saw until the hard spot has

to change speeds. There may be a card attached to or

been cut through.

near the saw giving recommended speeds for cutting

various metals. However, you may use the following

Gravity feed, in which weights are placed on

speeds:

the saw frame and shifted to give more or less

pressure of the saw blade against the material

-- Cold-rolled or machine steel, brass, and soft

being cut.

metals--136 strokes per minute.

All three types of feed mechanisms lift the blade

-- Alloy steel, annealed tool steel, and cast iron--

clear of the work during the return stroke.

90 strokes per minute.

-- High-speed steel, unannealed tool steel, and

Hacksaw Blades

stainless steel--60 strokes per minute.

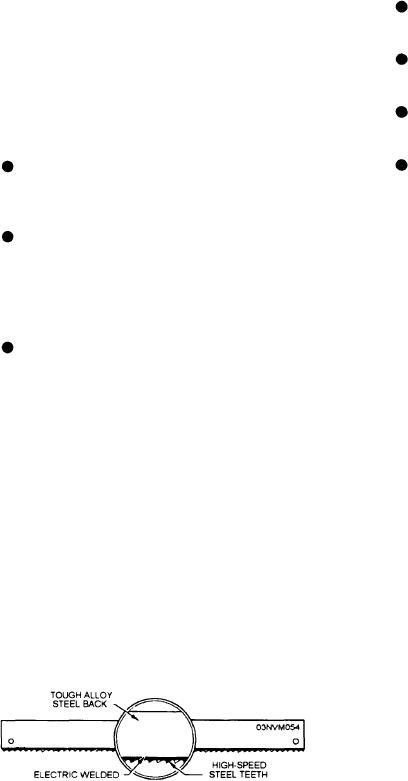

The blade shown in figure 5-54 is especially

designed for use with the power hacksaw. It is made

with a tough alloy steel back and high-speed steel

You should use a coolant for most power hacksaw-

teeth. This combination gives both a strong blade and

ing operations. (Cast iron should be dry when it is cut.)

a cutting edge suitable for high-speed sawing.

The coolant prevents overheating of the blade and stock

These blades vary as to the pitch of the teeth

along with increasing the cutting rate. A soluble oil

(number of teeth per inch). The correct pitch for a

solution with a mixture of the oil and water will be

suitable for most sawing operations. The normal mix-

ture for soluble oil is 40 parts water to 1 part oil. You

also may use a synthetic coolant.

METAL-CUTTING BANDSAW MACHINES

Metal-cutting bandsaw machines are standard

equipment on all repair ships and tenders. These

Figure 5-54.--Power hacksaw blade.

5-31