TM 55-2815-574-24

0003

FUEL SYSTEM - Continued

Combustion required for satisfactory engine operation is obtained by injecting, under pressure, a small quantity of

accurately timed, metered, and finely atomized fuel oil into the combustion chamber. Metering and timing during

fuel injection is accomplished by an upper and lower helix machined in the lower end of the injector plunger. The

continuous fuel flow through the injector serves, in addition to preventing air pockets in the fuel system, as a

coolant for those injector parts subjected to high combustion temperatures.

To vary the power output of the engine, injectors having different fuel output capacities are used. The fuel output

of the various injectors is governed by the effective stroke of the plunger and the flow rate of the spray tip. Since

the helix angle and the plunger design determines the operating characteristics of a particular injector it is

imperative that the specified injectors are used for each engine. If injectors of different types are mixed in an

engine, erratic operation will result and may cause serious damage to the engine or to the equipment which

it powers.

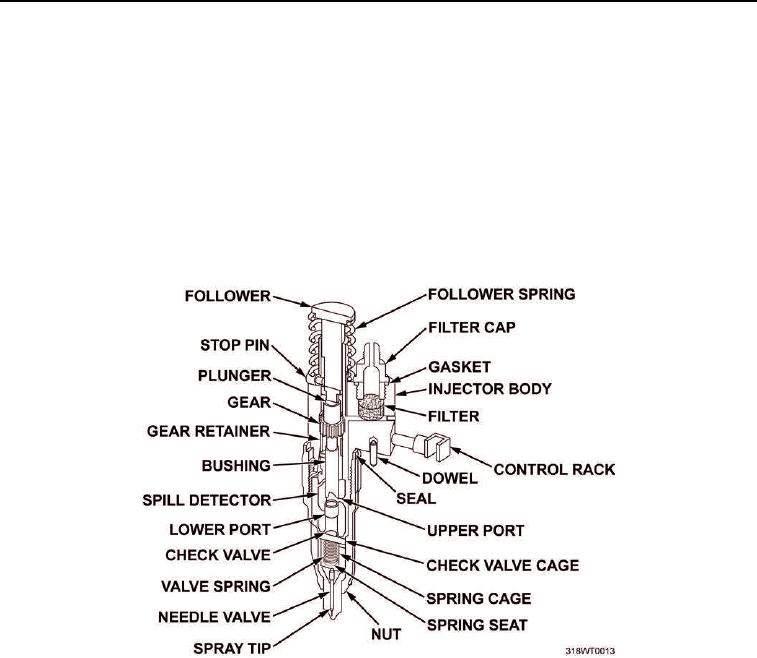

Figure 5. Injector.

Each fuel injector has a circular disc pressed into a recess at the front side of the injector body for identification

purposes. Each injector control rack is actuated by a lever on the injector control tube which, in turn, is connected

to the governor by means of a fuel rod. These levers can be adjusted independently on the control tube, thus

permitting a uniform setting or fine tuning of all injector racks. The fuel injector combines in a single unit all of the

parts necessary to provide complete and independent fuel injection at each cylinder.

Fuel, under low pressure, enters the injector at the inlet side through a filter cap and filter positioned over the

racks. From the filter, the fuel passes through a drilled passage into the supply chamber, that area between the

plunger bushing and the spill deflector, in addition to that area under the injector plunger within the bushing. The

plunger operates up and down in the bushing, and is supplied fuel through the two tunnel-shaped ports in the

bushing wall. The motion of the injector rocker arm is transmitted to the plunger by the follower which bears

against the follower spring. In addition to the reciprocating motion, the plunger can be rotated around its axis by

the gear which meshes with the control rack. To accomplish fuel metering, an upper helix and a lower helix are

machined in the lower part of the plunger. The helix relationship to the ports changes with the rotation of

the plunger.