TM 55-2815-574-24

0003

FUEL SYSTEM - Continued

Electronic Governor

The electronic governor system provides engine speed control in the place of mechanical linkages.

The actuator is a simple, proportional, electric solenoid having a sliding armature whose magnetic force is

proportional to the input coil current. The armature glides on anti-friction bearings and is balanced between the

force of the return spring and the magnetic force, thus providing a delay-free linear movement. The linear motion

is converted to an output shaft rotation by a crank arm that is connected to the injector control rack linkage, thus

controlling the fuel rate the engine is provided.

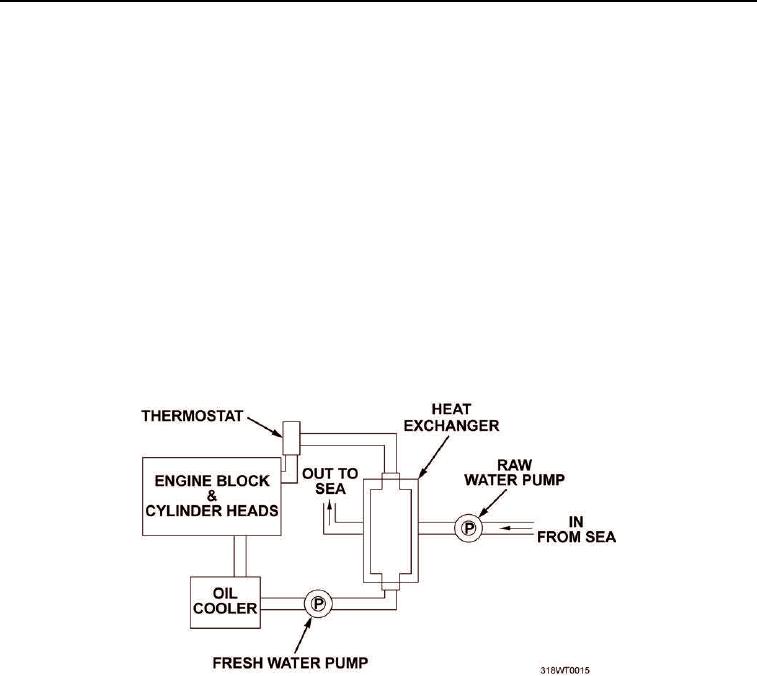

COOLING SYSTEM

To effectively dissipate the heat generated by the engine, a heat exchanger and raw water pump are used. The

system is provided with a centrifugal type water pump that circulates the engine coolant. The system incorporates

thermostats to maintain a normal engine operating temperature.

Upon starting a cold engine or when the coolant is below operating temperature, the coolant flow to the heat

exchanger is blocked or restricted by the thermostats in the thermostat housings. A bypass provides coolant

circulation within the engine during the warm-up period.

Figure 7. Cooling System.

In the heat exchanger cooling system, the coolant is drawn by the engine water pump from the heat exchanger

and is forced through the engine oil cooler, cylinder block, cylinder heads, and exhaust manifolds to the

thermostat housings. A bypass from the thermostat housings to the inlet side of the water pump permits

circulation of coolant through the engine when the thermostats are closed. When the thermostats are open, the

coolant flows through the heat exchanger where it is cooled. An engine driven raw water pump circulates raw

water (sea water) through the heat exchanger to lower the temperature of the engine coolant.