TM 55-2815-574-24

0003

LUBRICATION SYSTEM - Continued

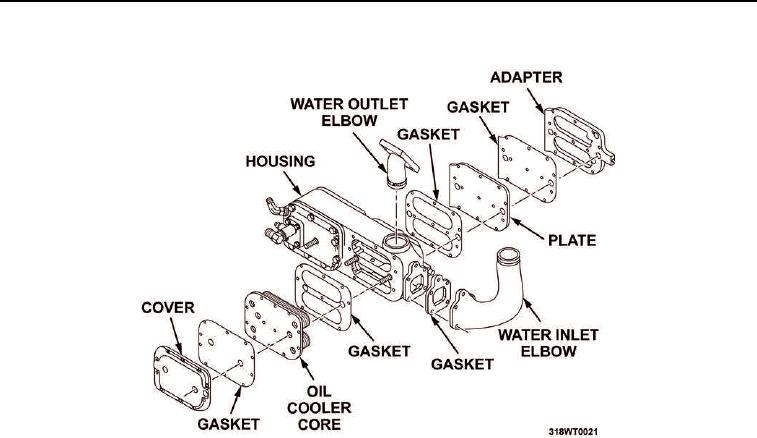

Figure 13. Oil Cooler.

Oil Dipstick

A steel ribbon-type oil level dipstick is used to check the quantity of oil in the engine oil pan. The dipstick is

located in the side of the cylinder block or the oil pan. The engine includes a 3/4 in. (1.9 cm) long rubber oil seal

inside the cap of the dipstick. This prevents the escape of vapors carrying oil from the dipstick tube.

Maintain the oil level between the full and low marks on the dipstick and never allow it to drop below the low mark.

No advantage is gained by having the oil level above the full mark. Overfilling will cause the oil to be churned by

the crankshaft throws causing foaming or aeration of the oil. Operation below the low mark will expose the pump

pick-up causing aeration and/or loss of pressure.

Crankcase Ventilation System

Harmful vapors which may be formed within the engine are removed from the crankcase, gear train, and valve

compartment by a continuous pressurized ventilating system. Breathing is through two openings in the rear main

bearing bulkhead of the crankcase and one large hole in the cylinder block rear end plate. They connect to a

central chamber (separated from chambers on each side which carry oil draining back from the cylinder heads)

that leads to an exit at the top of the cylinder block. The external tube(s) connects the cylinder block exit hole at

the rear of the cylinder head(s). Failure to use a rocker cover breather on the left bank head can result in

excessively high engine crankcase pressure. Excessive pressure can, in turn, cause crankshaft oil seal leakage

and/or loss of oil through the dipstick tube. The rocker cover(s) provides a large cross-sectional air flow area at

maximum height for efficient breathing and oil separation. A breather assembly is mounted at the openings in the

rocker cover(s). To index the breather assembly exhaust outlet on the current aluminum die cast valve rocker

covers, no disassembly is required. Insert a 1-1/8 in. outer diameter pipe or wood dowel into the exhaust outlet,

apply pressure, and rotate the outlet to the desired location.