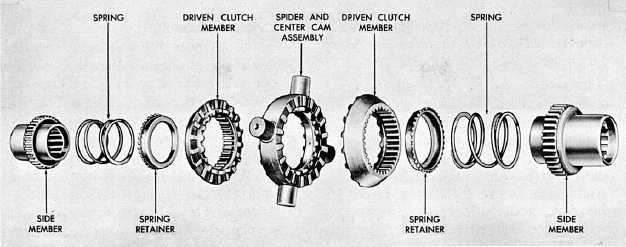

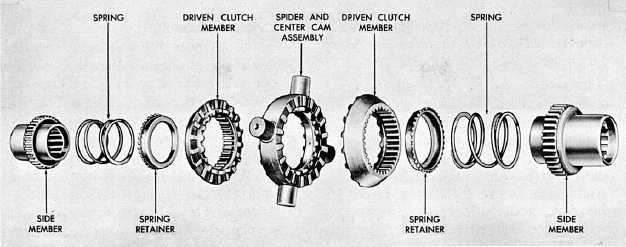

Figure 13-20.—No spin differential—exploded view.

governed by the speed of the wheel applying

tractive effort.

The no-spin differential does not contain pinion

gears and side gears as does the conventional

differential. Instead, it consists basically of a

spider attached to the differential drive ring gear

through four trunnions. It also has two driven

clutch members with side teeth that are indexed

by spring pressure with side teeth in the spider.

Two side members are splined to the wheel axles

and, in turn, are splined into the driven clutch

members.

AXLES

A live axle is one that supports part of the

weight of a vehicle and drives the wheels

connected to it. A dead axle is one that carries part

of the weight of a vehicle but does not drive the

wheels. The wheels rotate on the ends of the dead

axle.

Usually, the front axle of a passenger car is a

dead axle and the rear axle is a live axle. In four-

wheel drive vehicles, both front and rear axles are

live axles; in six-wheel drive vehicles, all three

axles are live axles. The third axle, part of a bogie

drive, is joined to the rearmost axle by a trunnion

axle. The trunnion axle attaches rigidly to the

frame. Its purpose is to help distribute the load on

the rear of the vehicle to the two live axles that it

connects.

Four types of live axles are used in automotive

and construction equipment. They are: plain,

semifloating, three-quarter floating, and full

floating.

The plain live, or nonfloating, rear axle, is

seldom used in equipment today. The axle shafts

in this assembly are called nonfloating because

they are supported directly in bearings located in

the center and ends of the axle housing. In

addition to turning the wheels, these shafts carry

the entire load of the vehicle on their outer ends.

Plain axles also support the weight of the

differential case.

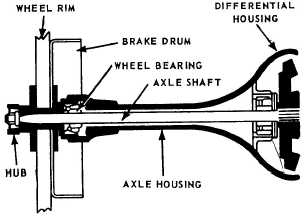

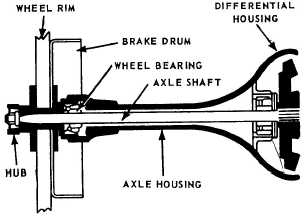

The semifloating axle (fig. 13-21) used on most

passenger cars and light trucks has its differential

case independently supported. The differential

carrier relieves the axle shafts from the weight of

the differential assembly and the stresses caused

by its operation. For this reason the inner ends of

the axle shafts are said to be floating. The wheels

are keyed to outer ends of axle shafts and the

outer bearings are between the shafts and the

housing. The axle shafts therefore must take the

stresses caused by turning, skidding, or wobbling

of the wheels. The axle shaft is a semifloating live

axle that can be removed after the wheel has been

pulled off.

Figure 13-21.—Semifloating rear axle.

13-17