be spur, spiral, hypoid beveled, or worm gears, as

illustrated in figure 13-17.

The function of the final drive is to change by 90

degrees the direction of the power transmitted through

the propeller shaft to the driving axles. It also provides

a fixed reduction between the speed of the propeller

shaft and the axle shafts and wheels. In passenger cars

this reduction varies from about 3 to 1 to 5 to 1. In trucks,

it can vary from 5 to 1 to as much as 11 to 1.

The gear ratio of a final drive having bevel gears is

found by dividing the number of teeth on the drive gear

by the number of teeth on the pinion. In a worm gear

final drive, you find the gear ratio by dividing the

number of teeth on the gear by the number of threads on

the worm.

Most final drives are of the gear type. Hypoid gears

(fig. 13-17) are used in passenger cars and light trucks

to give more body clearance. They permit the bevel

drive pinion to be put below the center of the bevel drive

gear, thereby lowering the propeller shaft. Worm gears

allow a large speed reduction and are used extensively

in larger trucks. Spiral bevel gears are similar to hypoid

gears. They are used in both passenger cars and trucks

to replace spur gears that are considered too noisy.

DIFFERENTIALS

Chapter 11 described the construction and principle

of operation of the gear differential. We will briefly

review some of the high points of that chapter here and

describe some of the more common types of gear

differentials applied in automobiles and trucks.

The purpose of the differential is easy to understand

when you compare a vehicle to a company of sailors

marching in mass formation. When the company makes

a turn, the sailors in the inside file must take short steps,

almost marking time, while those in the outside file must

take long steps and walk a greater distance to make the

turn. When a motor vehicle turns a comer, the wheels

outside of the turn must rotate faster and travel a greater

distance than the wheels on the inside. That causes no

difficulty for front wheels of the usual passenger car

because each wheel rotates independently on opposite

ends of a dead axle. However, to drive the rear wheel at

different speeds, the differential is needed. It connects

the individual axle shaft for each wheel to the bevel

drive gear. Therefore, each shaft can turn at a different

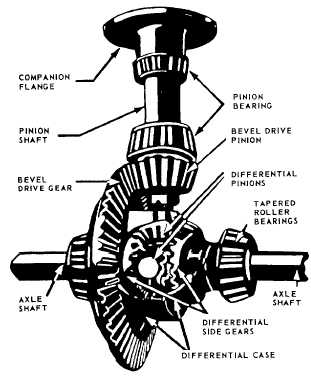

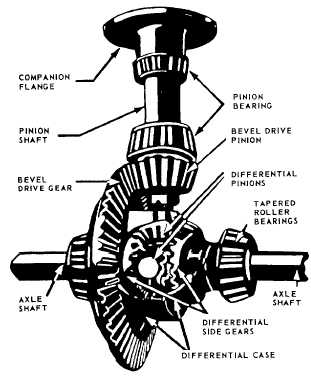

speed and still be driven as a single unit. Refer to the

illustration in figure 13-18 as you study

discussion on differential operation.

the following

Figure 13-18.-Differential with part of case cut away.

The differential described in chapter 11 had two

inputs and a single output. The differential used in the

automobile has a single input and two outputs. Its input

is introduced from the propeller shaft and its outputs

goes to the rear axles and wheels.

The bevel drive pinion, connected to the pinion

shaft, drives the bevel drive gear and the differential case

to which it is attached. Therefore, the entire, differential

case always rotates with the bevel drive gear whenever

the pinion shaft is transmitting rotary motion. Within the

case, the differential pinions (refereed to as spider gears

in chapter 11) are free to rotate on individual shafts

called trunnions. These trunnions are attached to the

walls of the differential case. Whenever the case is

turning, the differential pinions must revolve-one

about the other-in the same plane as the bevel drive

gear.

The differential pinions mesh with the side gears, as

did the spider and side gears in the differential described

in chapter 11. The axle shafts are splined to the

differential side gears and keyed to the wheels. Power

is transmitted to the axle shafts through the differential

pinions and the side gears. When resistance is equal on

each rear wheel, the differential pinions, side gears, and

axle shafts all rotate as one unit with the bevel drive gear.

In this case, there is no relative motion between the

13-15