pinions and the side gears in the differential case. That

is, the pinions do not turn on the trunnions, and their

teeth will not move over the teeth of the side gears.

When the vehicle turns a comer, one wheel must

turn faster than the other. The side gear driving the

outside wheel will run faster than the side gear

connected to the axle shaft of the inside wheel. To

compensate for this difference in speed and to remain

in mesh with the two side gears, the differential

pinions must then turn on the trunnions. The average

speed of the two side gears, axle shafts, or wheels is

always equal to the speed of the bevel drive gear.

Some trucks are equipped with a differential lock to

prevent one wheel from spinning. This lock is a simple

dog clutch, controlled manually or automatically, that

locks one axle shaft to the differential case and bevel

drive gear. This device forms a rigid connection

between the two axle shafts and makes both wheels

rotate at the same speed. Drivers seldom use it,

however, because they often forget to disengage the

lock after using it.

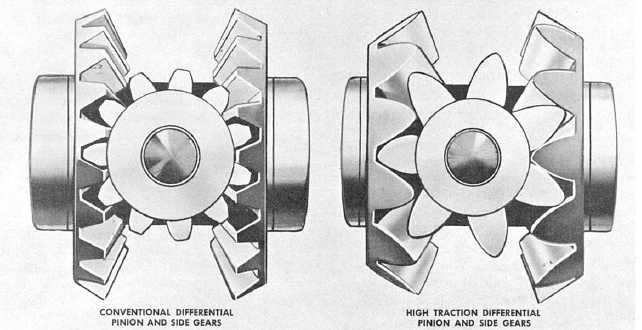

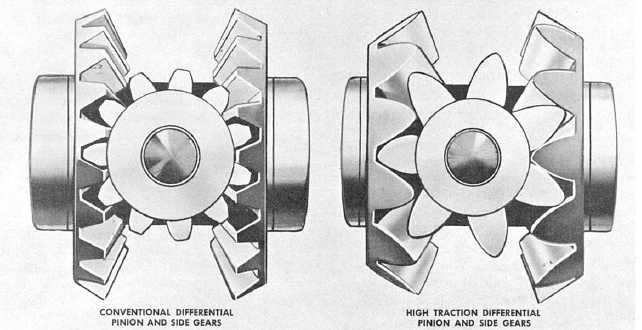

Several automotive devices are available that do

almost the same thing as the differential lock. One that

is used extensively today is the high-traction

differential. It consists of a set of differential pinions

and side gears that have fewer teeth and a different

tooth form from the conventional gears. Figure 13-19

shows a comparison between these and standard gears.

The high-traction differential pinions and side gears

depend on a variable radius from the center of the

differential pinion to the point where it comes in

contact with the side gear teeth, which is, in effect, a

variable lever arm. While there is relative motion

between the pinions and side gears, the torque is

unevenly divided between the two driving shafts and

wheels; whereas, with the usual differential, the torque

is evenly divided always. With the high-traction

differential, the torque becomes greater on one wheel

and lesson the other as the pinions move around, until

both wheels start to rotate at the same speed. When

that occurs, the relative motion between the pinion and

side gears stops and the torque on each wheel is again

equal. This device helps to start the vehicle or keep it

rolling when one wheel encounters a slippery spot and

loses traction while the other wheel is on a firm spot

and has traction. It will not work however, when one

wheel loses traction completely. In this respect, it is

inferior to the differential lock.

With the no-spin differential (fig. 13-20), one wheel

cannot spin because of loss of tractive effort and

thereby deprive the other wheel of driving effort. For

example, one wheel is on ice and the other wheel is on

dry pavement. The wheel on ice is assumed to have no

traction. However, the wheel on dry pavement will pull

to the limit of its tractional resistance at the pavement.

The wheel on ice cannot spin because wheel speed is

Figure 13-19.-Comparison of high-traction differential gears and standard differential gears.

13-16