CHAPTER 6

GEARS

CHAPTER LEARNING OBJECTIVES

Upon completion of this chapter, you should be able to do the following:

l Compare the types of gears and their advantages.

Did you ever take a clock apart to see what made it

tick? Of course you came out with some parts left over

when you got it back together again. And they probably

included a few gear wheels. We use gears in many

machines. Frequently the gears are hidden from view in

a protective case filled with grease or oil, and you may

not see them.

An eggbeater gives you a simple demonstration of

the three jobs that gears do. They can change the

direction of motion, increase or decrease the speed of

the applied motion, and magnify or reduce the force that

you apply. Gears also give you a positive drive. There

can be, and usually is, creep or slip in a belt drive.

However, gear teeth are always in mesh, so there can be

no creep and slip.

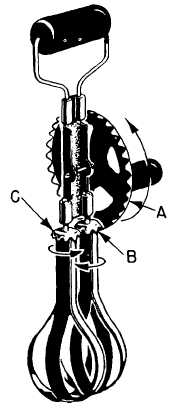

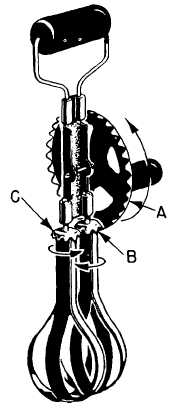

Follow the directional changes in figure 6-1. The

crank handle turns in the direction shown by the

arrow—clockwise—when viewed from the right. The

32 teeth on the large vertical wheel (A) mesh with the 8

teeth on the right-hand horizontal wheel (B), which

rotates as shown by the arrow. Notice that as B turns in

a clockwise direction, its teeth mesh with those of wheel

C and cause wheel C to revolve in the opposite direction.

The rotation of the crank handle has been transmitted by

gears to the beater blades, which also rotate.

Now figure out how the gears change the speed of

motion. There are 32 teeth on gear A and 8 teeth on gear

B. However, the gears mesh, so that one complete

revolution of A results in four complete revolutions of

gear B. And since gears B and C have the same number

of teeth, one revolution of B results in one revolution of

C. Thus, the blades revolve four times as fast as the crank

handle.

In chapter 1 you learned that third-class levers

increase speed at the expense of force. The same

happens with the eggbeater. The magnitude of force

changes. The force required to turn the handle is

greater than the force applied to the frosting by the

blades. This results in a mechanical advantage of less

than one.

TYPES OF GEARS

When two shafts are not lying in the same straight

line, but are parallel, you can transmit motion from

Figurc 6-1.—A simple gear arrangement.

6-1