If you pull the lever handle around one turn, its outer

end has described a circle. The circumference of this

circle is equal to 2x. (Remember that n equals 3.14, or

22/7). That is the distance you must apply the effort of the

lever arm.

At the same time, the screw has made one

revolution, raising its height to equal its pitch (y). You

might say that one full thread has come up out of the

base. At any rate, the load has risen a distance p.

Remember that the theoretical mechanical advan-

tage (T.M.A.) is equal to the distance through which you

apply the effort or pull, divided by the distance and

resistance the load is moved. Assuming a 2-foot, or

24-inch, length for the lever arm and a 1/4-inch pitch for

the thread, you can find the theoretical mechanical

advantage by the formula

27tr

T.M.A. = —

P

in that

r = length of handle = 24 inches

p = pitch, or distance between corresponding

points on successive threads = 1/4 inch.

Substituting,

A 50-pound pull on the handle would result in a

theoretical lift of 50 x 602 or about 30,000 pounds—15

tons for 50 pounds.

However, jacks have considerable friction loss. The

threads are cut so that the force used to overcome

friction is greater than the force used to do useful work.

If the threads were not cut this way and no friction were

present, the weight of the load would cause the jack to

spin right back down to the bottom as soon as you

released the handle.

THE MICROMETER

In using the jack you exerted your effort through a

distance of 2nr, or 150 inches, to raise the screw 1/4

inch. It takes a lot of circular motion to get a small

amount of straight line motion from the head of the jack.

You will use this point to your advantage in the

micrometer; it’s a useful device for making accurate

small measurements—measurements of a few

thousandths of an inch.

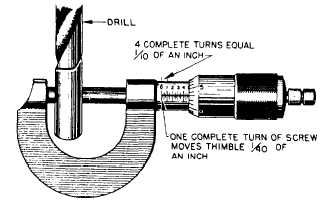

In figure 5-3, you see a cutaway view of a

micrometer. The thimble turns freely on the sleeve,

Figure 5-3.-A micrometer.

Figure 5-4.—Taking turns.

rigidly attached to the micrometer frame. The spindle

attaches to the thimble and is fitted with screw threads

that move the spindle and thimble to the right or left in

the sleeve when you rotate the thimble. These screw

threads are cut 40 threads to the inch. Hence, one turn

of the thimble moves the spindle and thimble 1/40 of

inch. This represents one of the smallest divisions on the

micrometer. Four of these small divisions make 4/40 of

an inch, or 1/10 inch. Thus, the distance from 0 to 1 or

1 to 2 on the sleeve represents 1/10, or 0.1, inch.

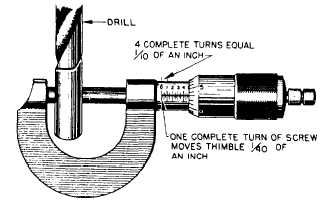

To allow even finer measurements, the thimble is

divided into 25 equal parts. It is laid out by graduation

marks around its rim, as shown in figure 5-4. If you turn

the thimble through 25 of these equal parts, you have

made one complete revolution of the screw. This

represents a lengthwise movement of 1/40 of an inch. If

you turn the thimble one of these units on its scale, you

have moved the spindle a distance of 1/25 of 1/40 inch,

or 1/1000 of an inch—0.001 inch.

The micrometer in figure 5-4 reads 0.503 inch, that

is the true diameter of the half-inch drill-bit shank

measured. This tells you that the diameter of this bit is

0.003 inch greater than its nominal diameter of 1/2

inch—0.5000 inch.

5-2