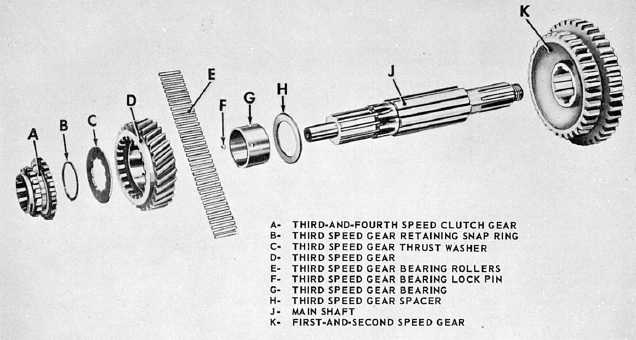

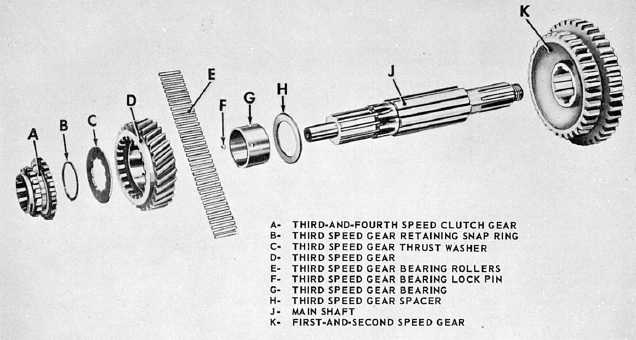

Figure 13-8.—Dissembled main shaft assembly.

(fig. 13-8, A) toward the third-speed gear (fig. 13-8,

D). This action engages the external teeth of the

clutch gear with the internal teeth of the third-speed

gear. Since the third-speed gear is rotating with the

rotating counter-shaft gear, the clutch gear also must

rotate. The clutch gear is splined to the main shaft,

and therefore, the main shaft rotates with the clutch

gear. This principle is carried out when the shift

lever moves from one speed to the next.

Constant-mesh gears are seldom used for all

speeds. Common practice is to use such gears for the

higher gears, with sliding gears for first and reverse

speeds, or for reverse only. When the shift is made to

first or reverse, the first and reverse sliding gear is

moved to the left on the main shaft. The inner teeth

of the sliding gear mesh with the main shaft first

gear.

SYNCHROMESH TRANSMISSION

The synchromesh transmission is a type of

constant-mesh transmission. It synchronizes the

speeds of mating parts before they engage to allow

the selection of gears without their clashing. It

employs a combination metal-to-metal friction cone

clutch and a dog or gear positive clutch. These

clutches allow the main drive gear and second-speed

main shaft gear to engage with the transmission

main shaft. The friction cone clutch engages first,

bringing the driving and driven members to the same

speed, after which the dog clutch engages easily

without clashing. This process is accomplished in one

continuous operation when the driver declutches and

moves the control lever in the usual manner. The

construction of synchromesh transmissions varies

somewhat with different manufacturers, but the

principle is the same in all.

The construction of a popular synchromesh clutch

is shown in figure 13-9. The driving member consists

of a sliding gear splined to the transmission main

shaft with bronze internal cones on each side. It is

surrounded by a sliding sleeve having internal teeth

that are meshed with the external teeth of the sliding

gear. The sliding sleeve has grooves around the

outside to receive the shift fork. Six spring-loaded

balls in radially drilled holes in the gear fit into an

internal groove in the sliding sleeve. That prevents

the sliding sleeve from moving endwise relative to the

gear until the latter has reached the end of its travel.

The driven members are the main drive gear and

second-speed main shaft gear. Each has external

cones and external teeth machined on its sides to

engage the internal cones of the sliding gear and the

internal teeth of the sliding sleeve.

The synchromesh clutch operates as follows: when

the driver moves the transmission control lever to the

third-speed, or direct-drive, position the shift fork

moves the sliding gear and sliding sleeve forward as a

unit until the internal cone on the sliding gear

engages the external cone on the main drive gear.

This action brings the two gears to the same speed

and stops endwise travel of the sliding gear. The

sliding sleeve slides over the balls and silently

engages the external teeth on the main drive gear.

This action locks the main drive gear and

transmission main shaft together as shown in

13-8