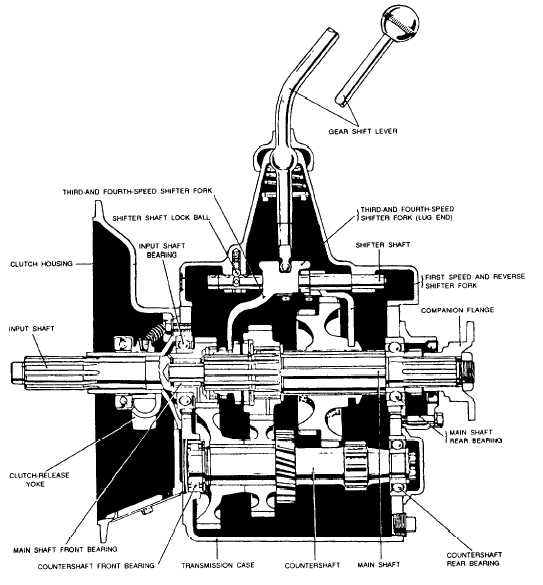

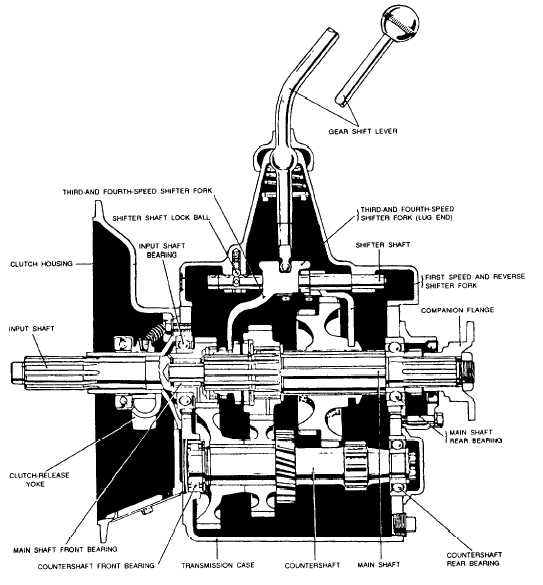

Figure 13-7.-Constant-mesh transmission assembly—sectional view.

All transmissions do not have four speeds forward,

and all do not have the same gear reductions at the

various speeds. Passenger cars, for example, usually

have only three forward speeds and one reverse speed.

Their gear ratios are about 3 to 1 in both low and reverse

gear combinations. You must remember, the gear

reduction in the transmission is only between the engine

and the propeller shaft. Another reduction gear ratio is

provided in the rear axle assembly. If you have a

common rear axle ratio of about 4 to 1, the gear

reduction from the engine of a passenger car to the rear

wheels in low gear would be approximately 12 to 1. In

high gear the ratio would be 4 to 1 since the transmission

would have no reduction of speed.

CONSTANT MESH TRANSMISSION

To eliminate the noise developed in the old spur-

tooth type of gears used in the sliding gear transmission,

the automotive manufacturers developed the constant-

mesh transmission that contains helical gears.

In this type of transmission, certain countershaft

gears are constantly in mesh with the main shaft gears.

The main shaft meshing gears are arranged so that they

cannot move endwise. They are supported by roller

bearings that allow them to rotate independently of the

main shaft (figs. 13-7 and 13-8).

In operation, when you move the shift lever to third,

the third and fourth shifter fork moves the clutch gear

13-7