ENGINEMAN 1 & C

Keep a record of the end play measurements

and refer to them when checking the main thrust

bearing. The normal wear of a pivoted shoe-type

thrust bearing is negligible even with years of use.

However, when a thrust bearing is new, there may

be slight settling of the leveling plates. If you

notice any increase in the end play, examine the

thrust shoe surfaces, and make all necessary

repairs.

In most cases, the main thrust bearing cap

must be removed for inspection. The opening is

of such size that it will permit the withdrawal of

the pair of ahead and astern thrust shoes located

in line with it.

C H E C K I N G E N D P L A Y W H I L E

RUNNING THE SHAFT.—The simplest method

of checking end play is to use a suitable measur-

ing instrument on any accessible part of the

propeller shaft while running the shaft slowly

ahead and astern. This is normally done at the

end of a run when the ship is maneuvering to ap-

proach the pier before the machinery and shaft

are cold. Although the speeds should be slow to

avoid adding deflections of bearing parts and

housing to the actual end play, these speeds should

be sufficient to overcome the rake of the shaft

and to ensure that the full end play is actually

taken up.

End play is measured with a dial indicator

mounted on a rigid support close to any con-

venient coupling flange. Occasionally a shaft may

have a shoulder turned on it for the sole purpose

of applying a dial indicator. Make sure that the

flange surface is free from paint, burrs, and rust

spots. The flange surface should also be well

oiled in order to prevent damage to the dial

indicator.

JACKING ON THE SHAFT FLANGE.—If

it is not feasible to measure the end play of a shaft

while running, your next choice is to jack the shaft

fore and aft at some convenient main shaft flange.

Use a dial indicator make certain that the shaft

movement is free, and guard against overdoing

the jacking force. The main difficulty associated

with the use of the jacking methods is in finding

suitable supports to ensure that no structural

damage will be incurred when jacking is done

against a main shaft flange coupling.

MAIN PROPULSION SHAFT

BEARINGS

You will be required to watch and maintain

the main propeller shaft bearings. These bearings

support and hold the propulsion shafting in align-

ment. They are divided into two general groups:

the main line shaft bearings (spring bearings), and

the stern tube and strut bearings.

MAIN LINE SHAFT BEARINGS

(SPRING BEARINGS)

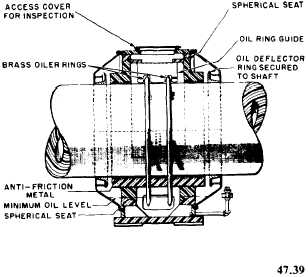

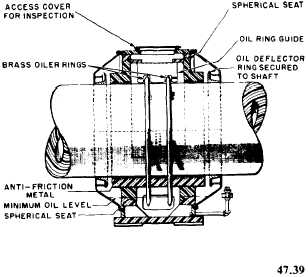

The main line shaft bearings (spring bearings)

are of the ring-oiled, babbitt-faced, spherical seat,

shell type. These bearings (figure 4-3) are designed

primarily to align themselves to support the weight

of the shafting. In many of the older, low-

powered ships, the bearings are not of the self-

aligning type and consist only of bottom halves.

The upper half of each assembly consists only of

a cap or cover (not in contact with the shaft)

designed to protect the shaft journal from dirt.

The spring bearings of all modern naval ships,

however, are provided with both upper and lower

self-aligning bearing halves.

The brass oiler rings (figure 4-3) hang loosely

over the shaft journal and the lower bearing half,

and are slowly drag fed around by the rotation

of the shaft. The upper half of the bearing is

Figure 4-3.—Main line shaft bearing.

4-8