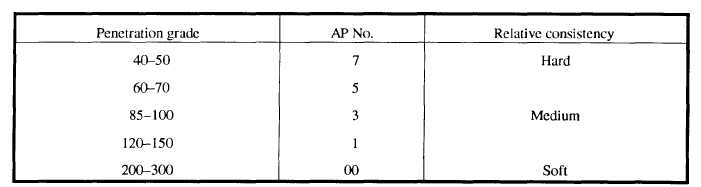

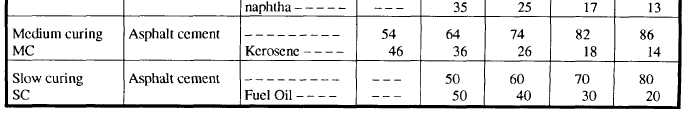

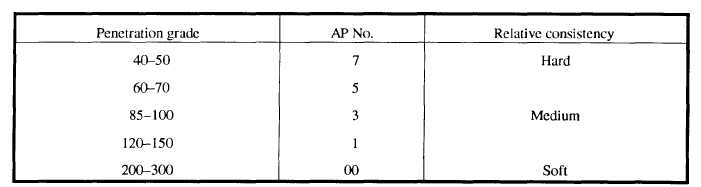

Table 8-2.-Penetration Grade and AP Number of Asphalt Cement

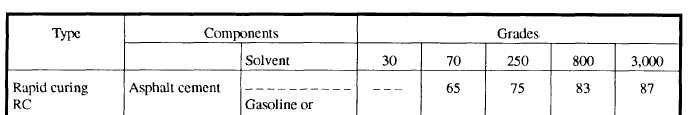

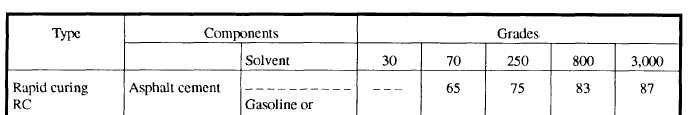

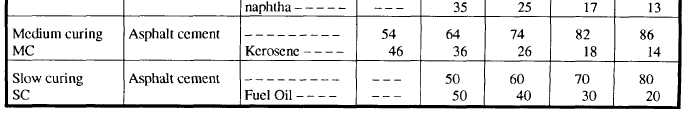

Table 8-3.-AsphaIt Cutback Composition (Expressed in Percent of Total Volume)

from 40 (hard) to 300 (soft) (table 8-2). The number is

derived from a penetration test that is the distance that

a standard needle penetrates the asphalt cement under a

standard loading weight, in a given time, under known

temperature conditions.

All asphalt cements are solid or semisolid at room

temperature (77°F) and must be converted to a fluid for

mixing with aggregate or for spraying. Asphalt cement

must be heated to a temperature ranging from 250°F to

350F, depending upon the grade of the asphalt cement.

The various penetration grades of asphalt cement

are suitable for different uses, such as plant mixes,

penetration macadam, and surface treatment. Soft

penetration grades of asphalt cement are preferred for

use in cold climates, medium grades in moderate

climates, and had grades in warm climates.

Asphalt Cutbacks

The special equipment needed to heat asphalt

cements is not always available. Since asphalt must be

in a fluid condition to spray or to mix with an aggregate,

the solid asphalt cement would not be suitable. Asphalt

cement (AC) can be made fluid by adding solvents

called Cutterstock or Flux Oil. Cutterstock maybe any

one of the more volatile petroleum distillate products.

The resulting combination is called Asphalt Cutback.

Exposure to air causes the petroleum distillate to

evaporate and leave the asphalt cement to perform its

function.

The rate of evaporation determines the type of

asphalt cutback that is in the mixture. Gasoline or

naphtha (highly volatile) will produce a rapid-cure

cutback (RC) with a curing time of 4 to 8 hours; kerosene

(medium volatility) will produce a medium-curing

cutback (MC) with a curing time of 12 to 24 hours; and

a fuel oil (low volatility) will produce a slow-curing

cutback (SC) with a curing time of 48 to 60 hours, Table

8-3 shows the percentage of components by grade for

the three types of asphalt cutbacks.

8-20