greater than the SWL of the wire rope, the test weight

will be computed from the SWL of the wire rope or if

the winch capacity is less than the SWL of the wire

rope, the test weight will be computed from the

capacity of the winch. The winch capacity is either

documented on the load charts or in the

manufacturer’s manual.

The formula for computing the SWL for a hoist

rope is the diameter of the rope squared multiplied by

8 or (D x D x 8 = SWL in tons).

Example: The wire rope on a crane is 1/2 inch in

diameter. Compute the SWL for the rope.

The first step is to convert the 1/2 into a decimal

number by dividing the bottom number of the fraction

into the top number of the fraction: (1 divided by

2 = .5). Next, compute the SWL formula: (.5 x .5 x 8

= 2 tons). The SWL of the l/2-inch wire rope is

2 tons.

The next factor to compute is the breaking

strength of the wire rope. On some wire rope spools,

the nominal breaking strength of the wire rope is

published; however, if the breaking strength is

unknown, a break test can be performed on the wire

rope. This is accomplished by cutting off sections of

the wire rope and placing each section of the rope on

a wire rope break test machine. The machine pulls the

wire rope apart and computes the breaking strength.

By testing several sections of the wire rope, you can

determine the average breaking strength for that type

of wire rope.

Overseas, Public Works Centers

normally have wire rope break test machines that can

be used by the NCF.

If the break test cannot be

performed, the rule of thumb used for finding the

breaking strength is to multiply the SWL by 5

(SWL x 5 = B.S.). For example, a l/2-inch wire rope

with a SWL of 2 tons has a breaking strength of 10

tons (2 x 5 = 10 tons).

REMEMBER: When the

single line wire rope end connection is assembled

with a wedge socket, the wedge socket only develops

70 percent of the breaking strength. Example: The

crane is rigged with l/2-inch wire rope with a wedge

socket end connection. The wedge socket only

develops seventy percent of the l/2-inch wire rope

B.S. of 10 tons, which gives the wire rope a B.S.

determined by an end connection of 7 tons. Swaged

socket, cappel socket, and the zinc (spelter) socket all

provide 100 percent of the breaking strength when

properly made.

The next factor to compute is the AWL by using

the factor of safety (F.S.). To compute the allowable

working load (AWL) of a wire rope, you must first

understand the following wire rope safety factors:

1. Rigging rope

a. 5 to 1 under operating conditions

b. 10 to 1 when used to lift personnel

2. Pendants or standing rope

a. 3.0 to 1 under operating conditions

b. 2.5 to 1 when erecting the boom

3. Ropes that wind on drums or pass over

sheaves

a. 3.5 to 1 under operating conditions

b. 3.0 to 1 when erecting the boom

For the auxiliary line, use the F.S. of 3.5 for wire

rope that winds on drums or passes over sheaves. The

formula for the F.S. is the breaking strength (B.S.),

determined by the type of end connection divided by

F.S. (Example: B.S. = 7 divided by 3.5 = AWL of

2 tons.)

The next factor to compute is the test weight.

This is done by multiplying the AWL of 2 tons by 110

percent (2 x 110% or 2 x 1.10 = 2.2 tons). Your test

weight for the l/2-inch wire rope is 2.2 tons. After the

test weight is figured, you must remember that the

hook blocks and rigging gear are weight that are part

of the test weight.

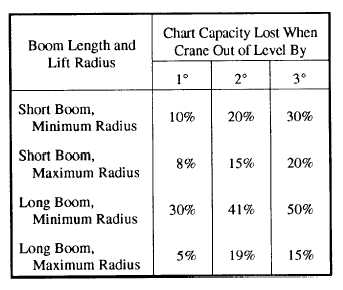

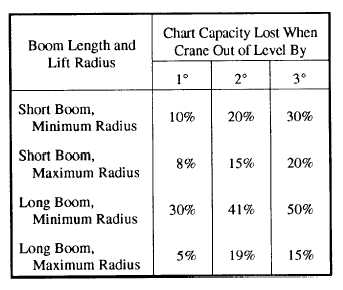

Leveling a crane cannot be overemphasized.

Cranes must be set up as per manufacturer’s

instruction, with the outriggers fully extended and the

crane leveled. Crane capacity is lost when the crane

is out of level by a few degrees (fig. 3-14). Most

Figure 3-14.-Crane capacity lost by crane out of level.

3-15