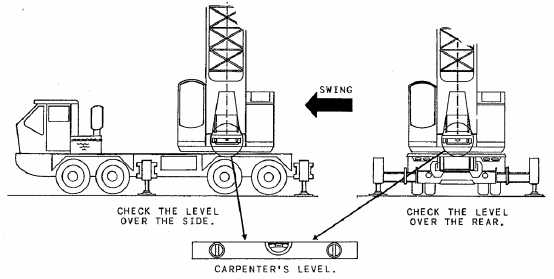

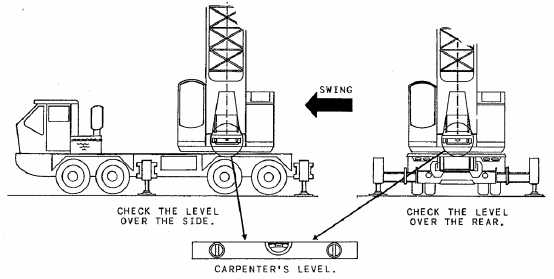

cranes have levels mounted on them, but the

levels are not always accurate. Use a 3-foot

builder’s level to check the level of the crane over

the rear and over the sides (fig. 3-15).

After the test weights are figured, you must

remember that the hook blocks and rigging gear

are weight that are part of the test weight. The

maximum test weight for this example is set up at

the 15-foot radius measurement over the side of

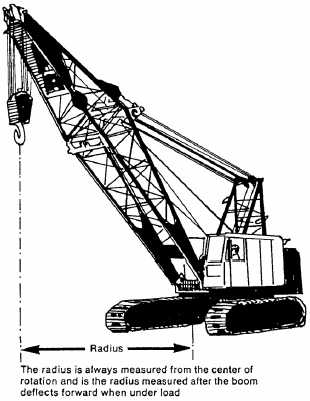

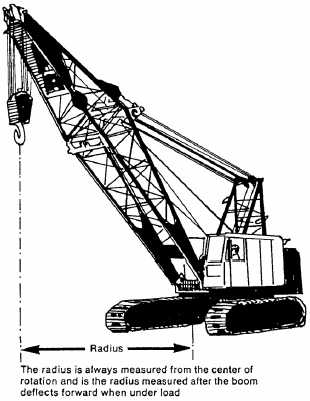

the crane. Crane radius is the measurement from

the center of rotation to the center of the hook (fig.

3-16).

The crane is weight-tested with the boom

rotated ninety (90) degrees from the longitudinal

axis of the crane carrier. It is strongly

recommended by NAVFAC P-307 that precautions,

such as attaching guy wires to the mane or placing

cribbing under the counterweight, be used to

preclude possible overturning of the crane in the

event of wire rope or mechanical failure. Cribbing

is normally used in the NCF.

Before testing of the crane can proceed, the

crane test mechanic and the certifying officer must

be present at the test site. The crane test

mechanic and the crane test director will perform

and complete the BDA inspection during and after

the testing of the crane. This document must be

signed by the test mechanic and test director.

One purpose of weight testing the crane is

to check and make sure the hydraulic rams on

the outriggers support the crane and the

maximum lifted load. A way to check the

hydraulic rams is with a grease pencil and a

ruler. Measure from a known vertical point

on the hydraulic ram housing and place a line

with the grease pencil on the ram (fig. 3-17).

Figure 3-16.—Crane radius.

After

each

test,

measure

this

known

measurement, and this will enable you to make

sure there is no slippage in the hydraulic system.

5.4 No-Load Test

The first part of the crane test procedure is the

no-load test. The procedure is as follows:

Figure 3-15.—Builder’s level leveling procedures.

3-16