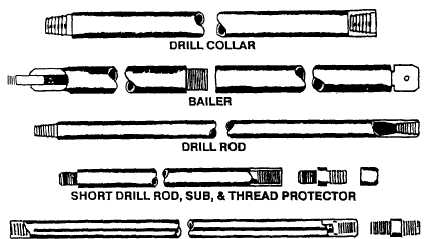

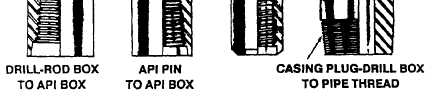

collar (fig. 9-9) joins the bits and drill pipe and helps

stabilize the bit and keeps the hole uniform and straight.

This collar is 10 feet long and has a diameter larger than

that of the drill pipe, yet small enough to clear the wall

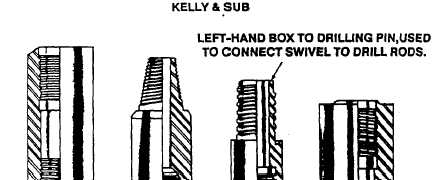

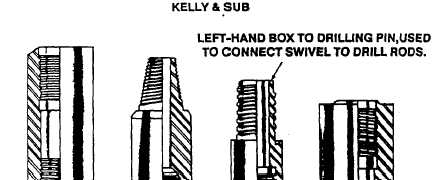

of the hole. The kelly sub, or wear sub, connects the

kelly to the drill pipe. When it becomes worn, it can be

changed instead of the entire kelly.

In areas where surface formations are soft or sandy,

it is necessary to set the casing to keep the walls of the

hole from caving and to prevent the hole from being

enlarged by the washing action of the circulating fluid.

Sometimes, the hole is reamed or enlarged to set the

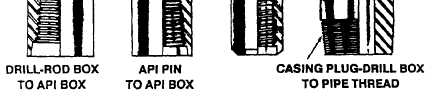

casing on a firm foundation. To run the casing, you

should attach a sub to the hoisting plug and threaded into

a length of the casing. Some casings are not threaded

and must be welded together. The welded casing can be

washed and cooled down by the mixing hose from the

mud pump and then run into the hole in the same manner

as the drill pipe. If the hole has caved so the casing will

not go down, attach the swivel to the casing with a sub

and circulate fluid through the casing. This is called

washing down and is sometimes used to wash the casing

to the bottom of a caving hole.

The kelly and drill pipe are hollow to allow fluid

mixtures of clay and water, air, foam, and so forth, to be

pumped through them to the bit. The fluid circulates

through the drill pipe and out through the bit, where it

sweeps under the bit and picks up the material loosened

by it. It then carries the material to the surface through

the space between the drill pipe and walls of the well.

Fluid from the well overflows into a ditch and passes

into a settling pit, where the cuttings settle. The fluid

free from coarse material and containing only

fine-grained clay in suspension, flows into another pit

and is picked up by the pump for recirculation in the

well.

Enough mud-laden fluid (drilling mud) must be

circulated to cool and clean the cutting tool properly and

to rise in the hole fast enough to carry the cuttings with

it. The weight and viscosity of the fluid, aided by the

Figure 9-9.-Drill steel, collars, and subs.

9-8