resource

of

a

particular

area.

The

information

available

normally

will

give

you

an

idea

as

to

the

geological

conditions,

such

as

terrain

and

type

material, approximate depth of an aquifer

or series of aquifers, quantities of water

that

may

be

expected

during

different

seasons of the year, average depth of the

water table, and drilling procedures and

problems that may be encountered.

Access to maps and publications is

usually

through

hydrographic

offices

either

on

a

state

or

national

level,

offices of the United States Coast and

Geodetic

Survey,

or

its

equivalent

in

other

countries,

geological

or

university

archives,

battalion

engineering

offices,

or

native

drillers.

When very little is known about the

water resources in a particular area, the

most valuable clues may come from an

inspection

of

the

outcropping

of

rock

format ions. You may need to verify your

conclusions by exploratory drilling, which is

the surest way to establish the existence

of

water-bearing

formations.

Exploratory

drilling

is

usually

initiated as part of the groundwater study

of an area before construction of water

wells at a particular site.

WELLS

Wells are classified into five methods

of construction. The methods are as follows:

dug, bored, jetted, driven, and drilled wells, Each type of

well has certain advantages and limitations;

and the type of well to be developed depends

upon

the

ease

of

construction,

storage,

capacity, limitations as to formations it can

penetrate,

and

ease

of

safeguarding

it

against

pollution.

A dug well is one in which the

excavation is Made by the use of picks,

shovels,

spades,

or

digging

equipment,

such as sand buckets or clamshell buckets.

A bored well is one in which the excavation

is made by the use of hand or power augers.

A jetted well is one in which the

excavation is made by the use of a high-

velocity jet of water.

A driven well is one which is

constructed by driving a pointed screen,

referred to as a drive point, into the

ground. Casings or lengths of pipes are

attached to the drive point as it is being

driven into the ground.

Dug, bored, jetted, and driven wells are

relatively

shallow,

Generally,

they

are

less than 100 feet deep and may be

constructed with hand tools. Drilled wells

in the NCF are normally drilled to the

depth of 1,500 feet and are constructed

with portable well drilling machines.

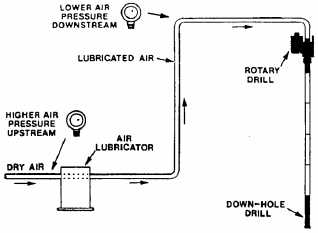

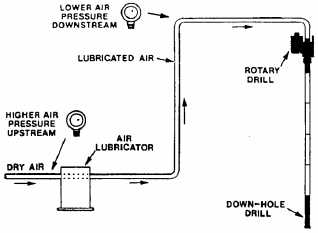

ROTARY DRILLING

When using a hand drill to bore a

hole, you press the cutting tool or bit

into

the

material

to

be

bored.

The

material is cut as you turn the bit by

means of the drill handle. During the

drilling

process,

chips

of

the

cut

material are carried to the top of the

hole by the flutes of the bit. A rotary

drilling rig operates on the same principle,

except for the method of raising the cut

material, This material is washed to the

surface by a fluid substance instead of

being carried by the bit itself. The bit

of a rotary drilling rig is attached to the

lower end of the drill pipe.

The methods of drilling for water

are referred to as rotary mud or rotary air

drilling. Rotary mud drilling is currently the

most common method used to drill wells and

is used where ground formations are loose

and unconsolidated. Mud drilling is also

used in consolidated formations but is not

very efficient. The rotary air drilling method

is preferred when ground formations are

consolidated.

A

limitation

of

the

air

drilling method is the cfm output of the air

compressor.

When rotary mud or rotary air drilling

operations

are

being

conducted

and

a

formation that is hard to penetrate is

encountered, the down-hole-drilling hammer

attachment can be used. The down-hole-

drilling hammer attaches to the lower end

of the drill pipe and rotates as well as

hammers (short rapid blows) against the

hard formation (fig. 9-4). To use the

Figure 9-4.-Down-hole-drilling (DHD).

9-4