plastering action of the fluid spiraling against the wall

of the well, prevent the wall from caving-in. The

consistency of the mud must permit the cuttings to be

held in suspension in the hole, yet permit them to settle

out in the surface pits. Although some local clays will

mix to an acceptable consistency, many do not. A

commercially prepared clay, such as Bentonite, must be

added to improve the density of the mud.

Kelly-Drive Rotary Drilling Operations

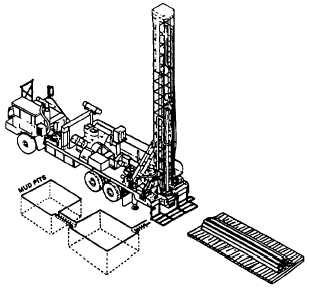

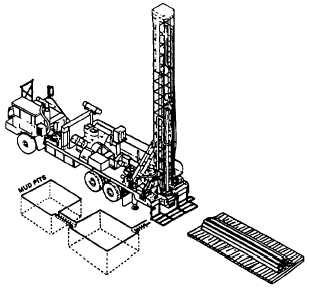

In well drilling, details of setting up the rig will vary,

depending on the rig used. Well drilling rigs can be

skid-mounted, trailer-mounted, truck-mounted, or even

self-propelled. In any case, it is necessary that the rig is

level and cribbed with dunnage before operations begin.

Keeping your rig level helps to keep the hole straight

during the drilling operation.

While the rig is being leveled, part of the crew can

excavate the mud pits (fig. 9-10). The size of the pit

depends on the water supply, depth of drilling, and the

type of material drilled. A fluid return ditch should be

dug from the drilled hole to the settling pit and from the

settling pit to the main pit. The ditches enter and leave

the settling pit in such a reamer that the flow of fluid is

reversed and causes the cuttings to settle, thus keeping

them from flowing into the main pit. The pits are lined

and sealed with drilling mud and then water is added.

Once the mud pits are full of water, the drilling mud can

be added and mixed to the right viscosity with the

mixing hose. The suction-hose screen is then placed in

the main pit at the opposite end of the return ditch. The

suction hose is submerged at all times but does not lie

on the bottom.

Keep the circulating fluid as clean and free from

abrasives as possible to protect the pump parts. The

settling pit should be cleaned when 75% full of cuttings

so that cuttings will not be placed in circulation. The pit

is cleaned when the rig is stopped for a drill pipe change,

or drill bit cleaning.

A water supply is essential when drilling wells by

the rotary method. There is no set rule as to the amount

of water required to drill any one hole. In some cases,

where the formations are compact, 3 to 4 gallons of

water per foot of hole drilled is sufficient. In other cases

where formations are loose and extremely porous, a

large supply of water is required. For ordinary purposes,

750 to 1,000 gallons of water per 8-hour shift is needed.

Skid-mounted and canvas tanks are usually apart of the

drilling outfit.

Figure 9-10.-Mud pits.

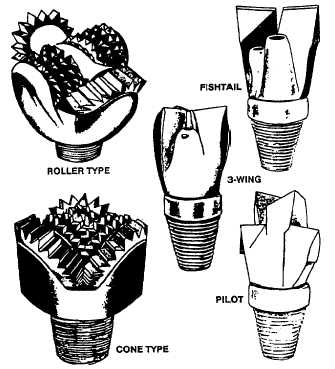

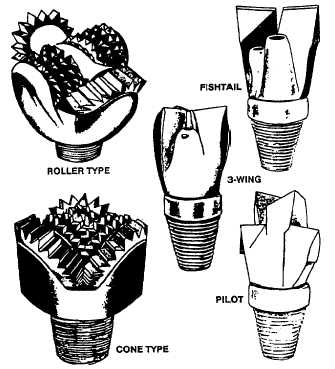

Even holes spaced only a short distance apart and

in the same soil formation may require different drilling

techniques. The drill supervisor must be capable of

selecting the best bit for penetrating a particular for-

mation. Some examples of rotary drilling bits are shown

in figure 9-11. Either the roller or the cone type of rock

bit can be used to penetrate moderately hard to hard

formations; a fishtail, three way, or pilot bit can be used

to penetrate soft formations and overburden material.

Figure 9-11.-Drill bits.

9-9