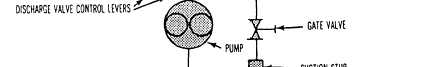

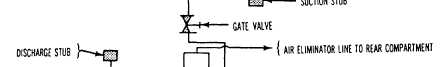

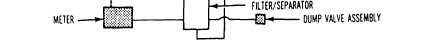

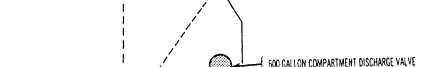

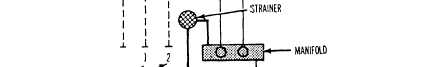

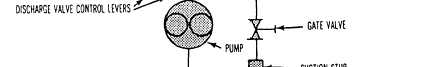

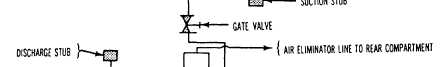

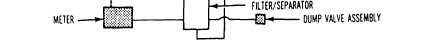

Figure 6-21.—Fuel-service truck diagram.

CAUTION

Allowing the engine to run with the

transmission engaged and the transfer case shift

lever in NEUTRAL without the PTO in the

ENGAGE position will cause bearing failure in

the transfer case.

Be sure to shift the

transmission gearshift lever to NEUTRAL

when not operating the power takeoff.

After the fuel dispensing pump is engaged set the

throttle rpm to the manufacturer’s recommended

setting. Move the discharge valve control levers to the

open position; and be sure, before pumping operations

begin, to attach the grounding wire to the vehicle being

serviced. Open the pump delivery line hose and squeeze

the nozzle operating lever to discharge the fuel.

After discharging the fuel, close the pump delivery

line gate valve, and move the discharge valve control

operating lever to the CLOSED position.TIhen close the

automatic dump valve drain tube valve. Return to the

driver’s compartment; set the rpms to idle, depress the

clutch and place the transmission gearshift lever in

NEUTRAL; then place the transfer power takeoff

shifting lever to DISENGAGED, and stop the engine.

When changing from one type of fuel to another,

drain and flush the fuel compartments, pump

filter/separator, service lines, manifold, meter, gauge,

and dispensing hoses and nozzles.

NOTE: All pumping mechanisms are not

controlled and operated in the same manner. Each make

or model operates differently. If you are in doubt as to

the proper pump operation and maintenance procedures,

study the operator’s manual and the caution and

instruction plates located near the pump and control

mechanisms.

Fuel Safety

Drivers of fuel tank trucks must observe safe driving

practices, some of which are listed below.

l Drive defensively and make allowances for other

drivers.

. Make turns only

intent to other drivers.

from proper lanes, and signal

Never leave the proper lane

6-27