Before making any cuts on a project, review the

project grade hub stakes (blue tops) to note their location

and how much you will have to cut or fill.

NOTE: Compaction of the surface must be done

before finish grading can start. When you finish

grading, it is better to cut 1/2 to 1 inch than to fill.

A technique used when performing blue topping

operations is to divide the project into sections, working

one section to final grade at a time. After the first section

is to grade, you now have a reference point to start from

to grade the other sections. As with any earthmoving

equipment, it is best to have a level starting point.

When working each section, do not let the material

build up into piles that the grader will have to run over.

Windrow the material to the end or off the section and

have a loader pickup the excess material and move it.

If there is room, the excess material can be windrowed

off the project for later removal.

When cutting, drag the blade over the top of the hub

stake. Final grade is reached when the blade skims the

top of the hub stake. Do not cut too deep and knock the

hub stake out of the ground. When several passes are

required to achieve final grade, the “cut boss” should

clean off the top of the stakes so you can see them for

your next pass.

Grader Estimates

A part of planning a construction project is

estimating how long it will take to complete a

construction activity.

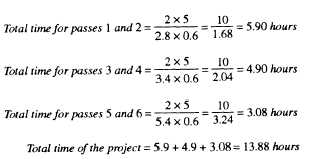

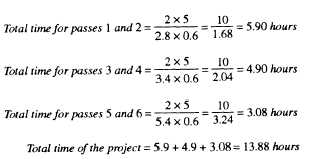

A work-output formula for

preparing preliminary estimates for grader operations is

as follows:

W h e re

Total time =

P =

D =

S

=

E =

Hours required to complete a grader

operation

Number of passes (P) the grader

must take to complete the operation

Distance (D) traveled in each

pass expressed in miles

Speed (S) expressed in miles per hour

Grader efficiency (E) factor

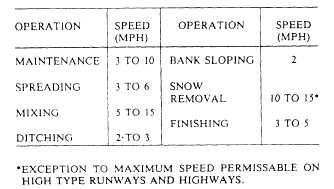

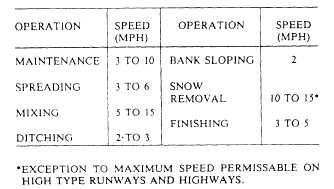

The most difficult factor to estimate is the speed of

the grader. As work progresses on a construction

10-15

activity, conditions may require that the speed estimates

of the grader be increased or decreased. A work output

is computed for each operation that is performed at a

different rate of speed. The total time of each operation

for each different speed is added together to compute the

total time of the grader operation. Table 10-1 lists the

speeds normally used in various grader operations.

The grader efficiency (E) factor takes into account

the fact that a 60-minute work hour rarely is attained.

Efficiency varies, depending upon supervision, operator

skill, maintenance requirements, and site conditions. A

value of 60 percent is average, computed in decimal

form as 0.6. The efficiency factor can be adjusted on

each job.

Example problem:

Five miles of gravel road is to be leveled and

reshaped by using a grader with a 12-foot blade. Six

passes are estimated to complete the leveling and

reshaping operation.

The type of material permits

passes 1 and 2 to be performed in second gear at 2.8

mph, passes 3 and 4 in third gear at 3.4 mph, and passes

5 and 6 in fourth gear at 5.4 mph. The efficiency factor

for the job is 60 percent.

Calculate how long it will take to complete the job.

Always round your answer to the next higher

number. In this case, 13.88 is rounded to 14 hours.

Table 10-1.-Approximate Speed Ranges Used in Various

Grader Operations