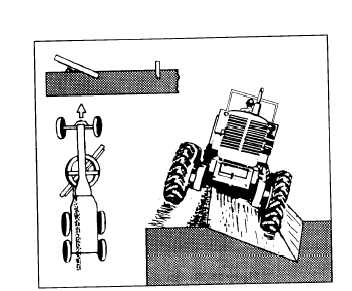

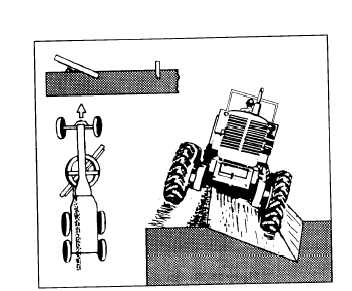

Figure 10-25.-Ditch cut.

Ditch Cut

The first step performed on a road project is to

establish drainage normally through the use of a ditch.

To construct a ditch, you must know how to cut a straight

ditch line and make sure the ditch line stakes fit the

plans.

The first cut to make is the marking cut. The

marking cut is a 3- to 4-inch-deep cut made with the toe

of the blade (fig. 10-23). The toe of the blade is

positioned in line with the outside edge of the front tire.

For cutting, the blade pitch is adjusted until the top and

bottom edges of the moldboard are aligned

Perpendicular to the ground. The marking cut is a

technique used for easier grader control and straighter

ditches.

After the marking cut, position the blade at about a

45-degree angle to perform an efficient ditch cut (fig.

10-24). The toe of the blade is positioned in line with

the center of the lead tire, while the heel of the blade is

raised to allow the windrow to form either inside or

outside the rear wheels (fig. 10-25). It maybe necessary

to remove the scarifier teeth to keep them from

interfering with the blade.

NOTE: Do not forget to lean the top of the front

wheels in the direction of the flow of the cut material.

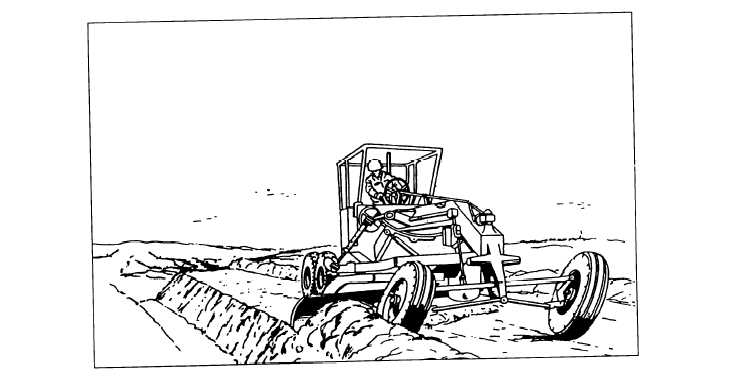

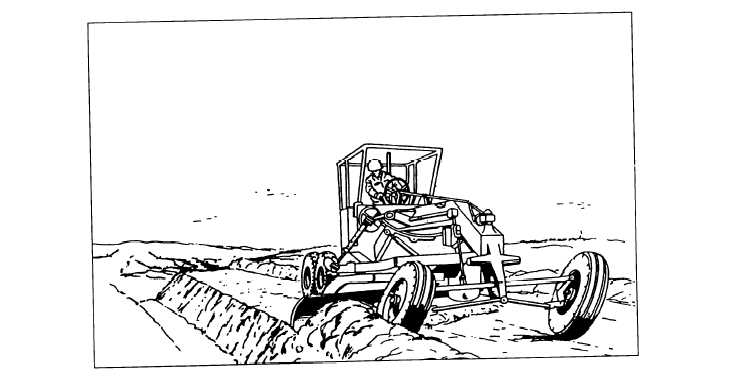

After each ditch cut, the material should be

windrowed or spread towards the middle of the road,

away from the ditching operations. This technique is

called shoulder pickup. To spread the windrow away

from the ditch, position the front grader tire on the inside

of the windrow. Side shift the blade and the circle so the

toe is positioned to the outside of the windrow, as shown

in figure 10-26. The heel is positioned to allow the

windrow to side cast inside the rear tandem tires. The

purpose of the shoulder pickup is to move the windrow

away from the foreslope of the ditch.

Figure 10-26.-Shoulder pickup.

10-11