Figure 10-12.-Scarifiers.

to be penetrated by the blade. The scarifier is either

pulled or pushed through the material, depending on the

make and model of the grader and the position of the

scarifier unit on the equipment. Figure 10-12 shows

two types and locations of scarifies on graders.

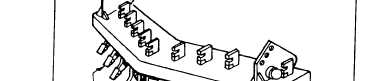

The teeth, consisting of slender shanks with

replaceable caps, are set in a V-shaped bar (fig. 10-13).

The shanks are wedged or clipped in place and maybe

adjusted for height or removed completely.

A scarifier with all the teeth is used for shallow

penetration and light work. For hard or deeper

penetration, remove every other tooth.

GRADER OPERATIONS

Although the grader is a multipurpose machine that

is capable of doing a variety of jobs, the performance of

the grader depends largely upon the skill of the operator.

The extensive skill required to perform as an effective

grader operator is only gained through practice and

on-the-job experience.

Wheel Lean

The proper use of the front wheels is a great aid in

. .

both steering and grading. In grading, lean the top of

Figure 10-13.-Scarifier teeth.

Figure 10-14.-Proper wheel lean.

10-6