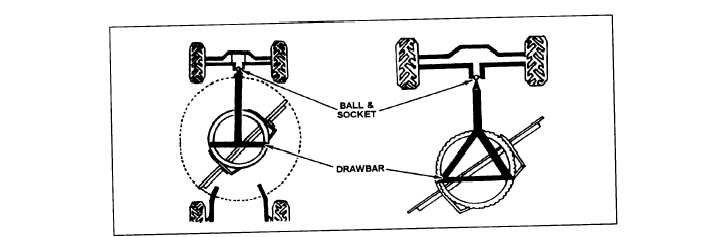

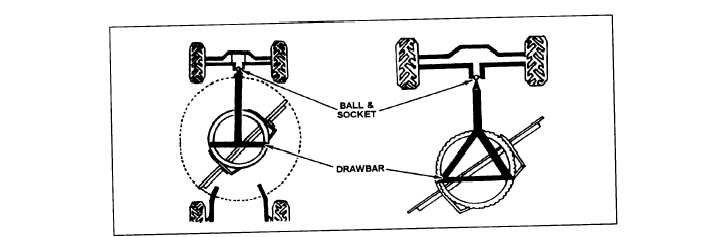

Figure 10-10.-Drawbar.

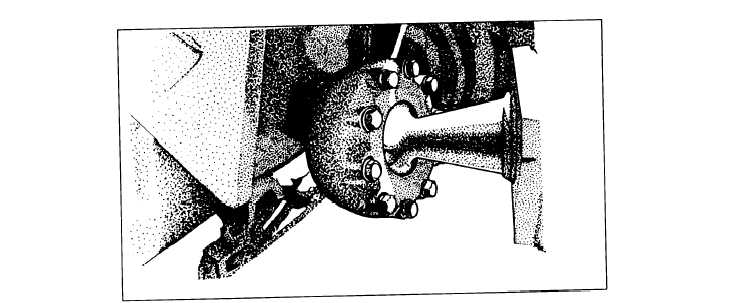

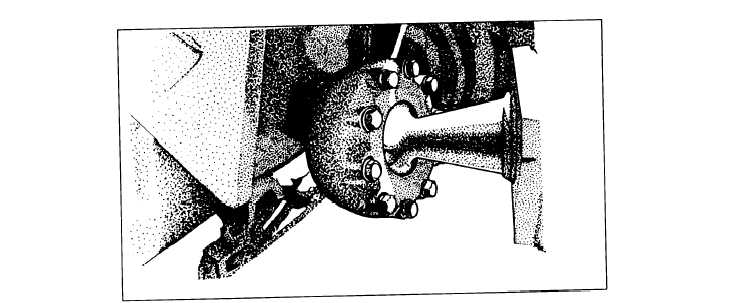

Figure 10-11.-Ball-and-socket connection.

off the heel. When the toe of the blade is to your right,

the material will side cast to the left and spill off the heel.

The moldboard is supported and held in position

by curved brackets, called circle knees and side shift

guides, as shown in figure 10-6. They are attached to

the underside of a rotatable ring, called the circle.

Cycle

The circle is a tooth-ring gear that is rotated in a

supporting frame by the circle reverse mechanism. The

circle teeth may be internal (fig. 10-8, view A) or

external (fig. 10-8, view B), depending on the make and

model of the grader.

The circle is turned by a spur-pinion gear (fig. 10-9)

that meshes with the circle teeth. The spur-pinion gear

is held by the drawbar and is controlled by a lever in

the operator’s cab. Engaging the spur-pinion gear allows

rotating the circle to the desired blade angle position.

Drawbar

The drawbar is a V- or T-shaped connection

between the front of the grader frame and the circle (fig.

10-10). The drawbar holds the circle rigid and is

fastened by a ball and socket that allows angular

movement from side to side and up and down (fig.

10-11). The drawbar carries the full-horizontal load on

the blade. Other components provide vertical and side

support.

Scarifier

The scarifier is a hydraulically controlled unit with

a set of teeth used to break up material too compacted

10-5

~.--- --- yv . . v. “Uv..v.

-.*” “KXVUS8UA8XL AVLbb WA UIG