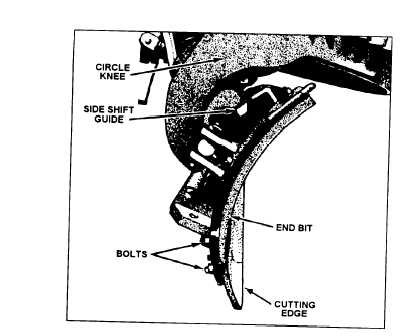

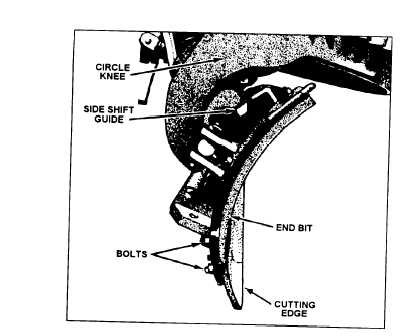

Figure 10-6.-Moldboard.

Figure 10-7.-Blade heel and toe.

tool of the grader that can be lifted, lowered. rotated.

tilted forward and backward, shifted to one side or the

other, and angled horizontal (fig. 10-6).

The cutting edge and end bits are bolted to the

moldboard. They act as wear plates and must be

replaced or reversed when worn or broken. In most

cases, the bolts will have to be replaced too.

NOTE: Always keep enough cutting edges and end

bits on hand to protect the moldboard from wear or

damage.

The length of the blade is normally 12 or 14 feet.

The curve shape of the blade causes dirt to roll and mix,

as it is cut and moved. The rotary movement of the dirt

combined with the angle of the blade causes a side-cast

drift of the material.

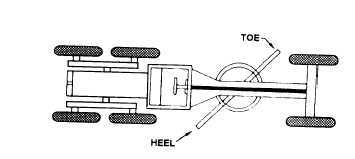

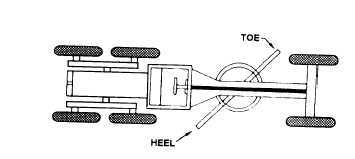

When the blade is angled to position one end ahead

of the other, two terms are used to designate the blade

ends. They are the heel and the toe of the blade. Figure

10-7 shows that the toe is the leading edge of the blade;

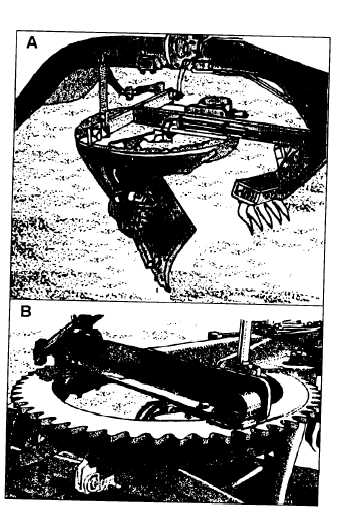

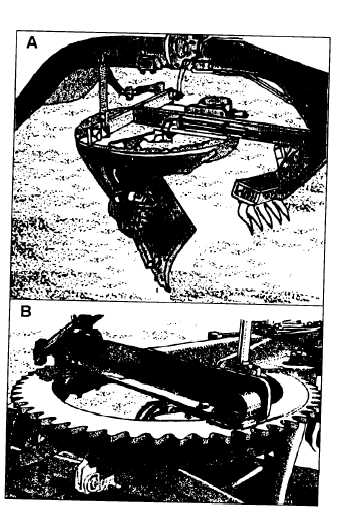

Figure 10-8.—Circle.

the heel is the trailing edge. When the blade is turned

so the toe is to your left, as you sit in the operator’s

seat, the material will side cast to your right and spill

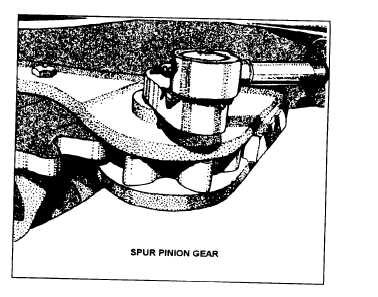

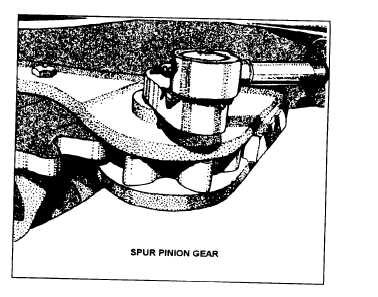

Figure 10-9.-Spur-pinion gear.

10-4