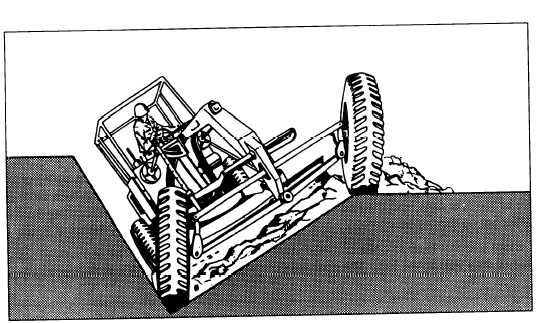

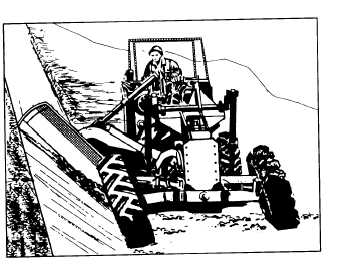

Figure 10-15.-Wheel lean on a ditch slope.

the wheels in the direction of the flow of material (the

heel of the blade). For example, as shown in figure

10-14, viewed from the operator’s seat, the toe of the

blade is extended to the right of the grader side casting

the material to the left. The material cut at the toe of the

blade causes a pulling force exerted on the front end of

the grader, wanting to pull the grader to the right. By

leaning the top of the wheels to the left (heel) counteracts

this pulling force.

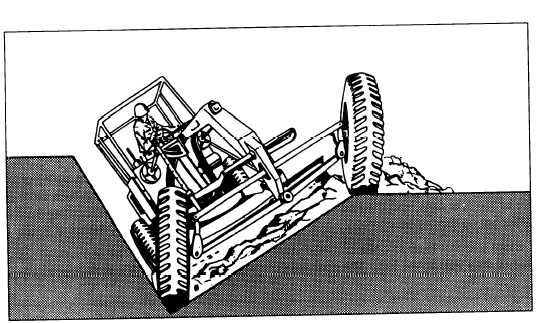

When grading a ditch foreslope, as shown in figure

10-15, lean the top of the wheels enough to keep them

in a vertical working position. This will lean

technique will do the following: (1) keep the grader from

drifting down the bottom of the foreslope and (2) keep

the grader wheels from climbing the walls of the

backslope.

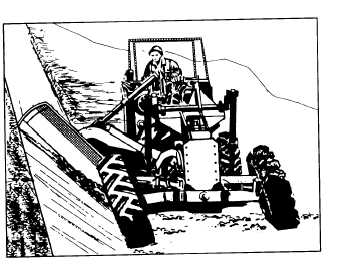

On high bank-cutting operations, lean the top of the

wheels toward the bank, as shown in figure 10-16. The

blade engaged in the bank cut causes a pushing force,

wanting to push the grader away from the bank. The

wheel lean counteracts the force and helps keep the

blade properly positioned for bank cutting.

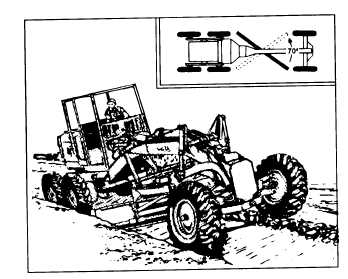

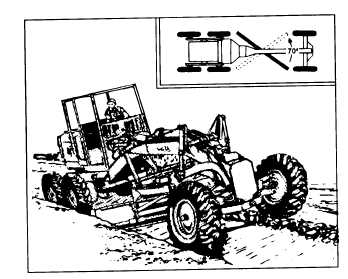

Turning Around

When jobs are confined to short stretches or narrow

widths, rotating the blade from forward to reverse

grading position requires a circle reverse movement of

only about 70 degrees (fig. 10-17). When reverse

blading, the cut pass is normally made in reverse, while

the side casting of the windrow pass is made on the

forward trip, saving valuable time and speed in

Figure 10-16.—Wheel lean on high bank-cutting operations.

Figure 10-17.-Changing the blade from forward to reverse.

10-7