operations by eliminating frequent turning around of the

grader.

NOTE: Reverse grading is only for operators who

have developed superb skills in grader operations.

For reverse blading, if the scarifier unit is located

just in front of the blade (behind the front axle), remove

all of the scarifier teeth and fully retract the scarifier unit.

This allows a clear area when changing the direction of

the blade. When reverse blading, set the blade so the toe

is just outside of the rear tires, and the heel side casts

outside the front tire on the opposite side.

NOTE: Store scarifier teeth in collateral equipage

or in a location so they will not be lost. The operator is

responsible for all of the scarifier teeth assigned to the

grader.

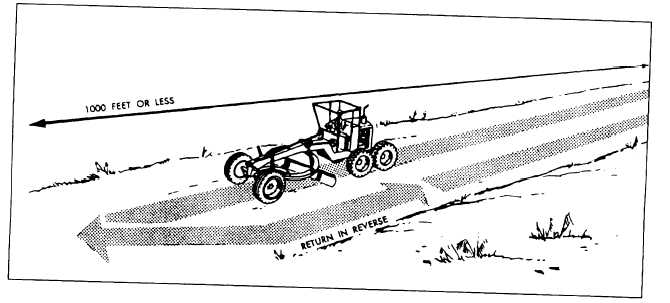

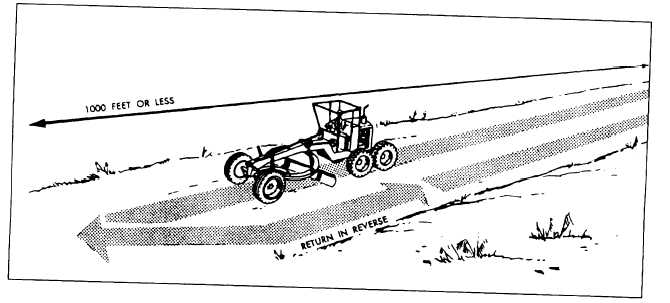

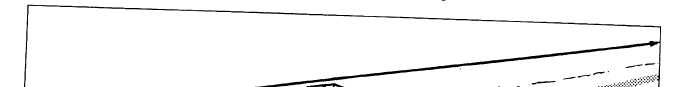

When you are grading on a project where the passes

are less than 1,000 feet, it is more efficient to grade in

recerse or vack the grader the entire distance to the

starting point than it is to turn around and continue work

from the far end, as shown in figure 10-18.

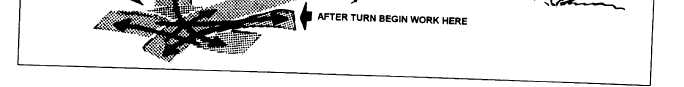

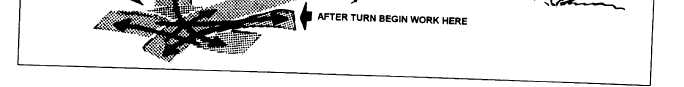

When you are grading on a projuct where the passes

are 1,000 feet or more, it is then more efficient to turn

the grader around and start blading from the far end back

to the starting point, as shown in figure 10-19.

The combined maneuvering advantages of the

leaning front wheels and the rear tandem drive are a big

Figure 10-18.-Elinimate unproductive turning around.

Figure 10-19.-Turning around.

10-8