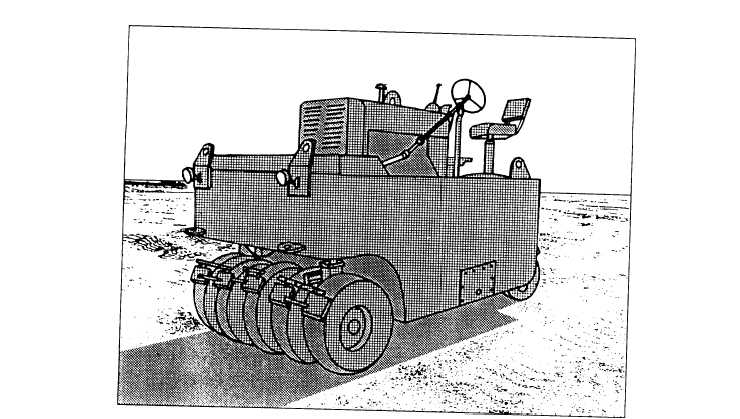

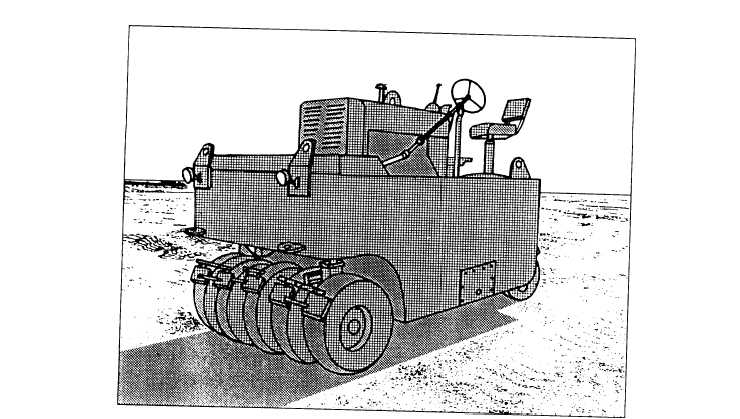

Figure 11-42.—Pneumatic-tired roller.

lifts, a smooth drum is all the compaction equipment

required. The smooth drum compacts lifts of- 4 to 8

inches and seals the surface to allow the excess water to

drain. Unlike the sheepsfoot drum, smooth drum rollers

concentrate the full width of the drum. The total

dynamic force is slightly less, because more of the drum

is in contact with the ground.

PNEUMATIC-TIRED ROLLERS

The pneumatic-tired rollers are widely used for

compaction of subgrades, bases, bituminous mixes, and

many types of material. They have rubber tires instead

of steel tires or drums and generally feature two tandem

axles, with three or four tires on the front axle and four

or five tires on the rear, as shown in figure 11-42. They

are aligned so the rear tires cover the spaces left between

the tracks of the front tires. The tires are mounted in pairs

that can oscillate, or singly with spring action, so tires

can move down into soft spots that would be bridged by

a steel drum. The rubber tires add to their downward

pressure a kneading effect, as material is pressed

toward spaces between the tires.

Pneumatic-tired rollers can be ballasted to adjust the

weight. Depending on size and type, the weight may

vary from 10 to 35 tons. However, more important than

gross weight is the weight per wheel for the material

being compacted.

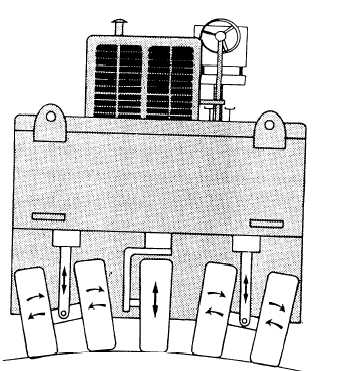

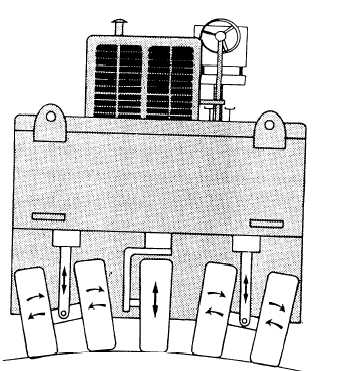

Figure 11-43.—Action of a pneumatic-tired roller.

CAUTION

Pneumatic rollers ballast with water are top

heavy and are very unstable when operating on

uneven terrain.

11-22