propelled. This concentric force tends to move the

material under the wheel, rather than to push it away.

These forces result in a more direct vertical force than

those of the forces under the tiller wheel.

ROLLING TECHNIQUES

Roller techniques arc basically the same with any

type of roller. Some things you must consider are

steering, changing direction and speed, and rolling

sequence.

Steering

Steering sharply causes scuffing and damage to the

surface; therefore, turns should be made slowly and

gradually. You may have to back up several times to

complete a turn.

Changing Direction and Speed

Starting and stopping should be done gradually to

avoid scuffing the surface. Start stopping well ahead of

the point where you want to stop. Engage the direction

control slowly to avoid any wheel spin.

Rolling speed is 1 1/2 to 3 miles an hour. You must

develop a rolling sequence to ensure the compaction is

uniform throughout the fill.

Rolling Sequence

Overlapping is part of the rolling sequence. When

rolling deep, loose fills, you should overlap at least half

the drum width. Gradual extension of the rolled material

into the unrolled area makes possible greater con-

centration of weight on local ridges and high spots.

In rolling a graded area with a side slope, as a

crowned or banked road, you should work from the

bottom to the top. The lower edges of the rolls have a

tendency to push downhill, which can be best resisted

by compacted material. In working uphill, the creep of

soil away from the upper edge helps to preserve the

slope.

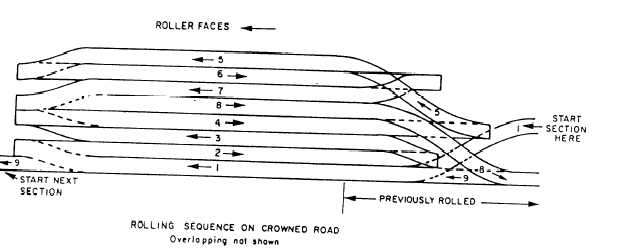

A crowned road is rolled according to the pattern

shown in figure 11-46, starting at one edge and working

to the center line. Then move diagonally to the opposite

side and work to the center line from that side. Each

rerolling is done in the same manner.

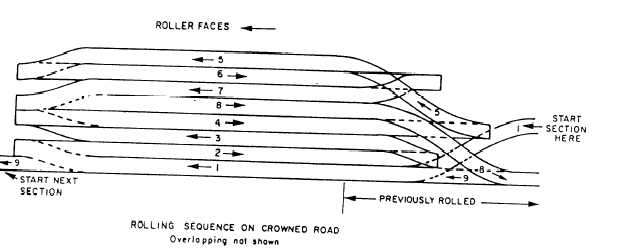

It is efficient to roll in sections as long as you can

overlap the sections, as shown in figure 11-47.

Banked or sloped elevated curves are rolled in the

direction of travel, from the bottom (low side) to the top,

as shown in figure 11-48. The rolling transition from the

road crown to the bank curve is made by a diagonal from

the center of the crown to the low side of the bank. The

rolling transition from bank to crown is made straight to

the adjoining low side of the road crown.

Rolling should be continued until no compaction

advantage is noted on the fill from successive passes.

Too much water in the fill material may make

compaction impossible. This may require scarifying and

windrowing the fill to aerate the material. A rubbery, or

spongy, rolling action of the fill that springs back into

nearly its original condition when the rollers have

passed may indicate trapped water below the surface.

The robbery, or spongy, area may require stabilization

by other means, such as excavating the area and

Figure 11-46.-Crowned road rolling sequence.

11-24