NOTE: Do NOT use a detergent that is designed to

break down grease or oil, as this will break down the

petroleum products used in the bituminous mix.

NOTE: Ensure roller tires and drums are free of

debris, such as sand, mud, dirt, and so forth, before

rolling a hot bituminous mix.

CAUTION

Avoid prolonged skin contact with and

inhalation of vapors from bituminous opera-

tions.

When you are rolling bituminous materials, the

rollers should move at a slow, uniform speed with the

drive wheels positioned toward the paver. The speed

should not exceed 3 mph for steel-wheeled rollers or 5

mph for pneumatic-tired rollers. Asphalt rollers must be

kept in good condition and should be capable of being

reversed without backlash. The line of rolling should not

be suddenly changed or the direction of rolling suddenly

reversed, thereby displacing the mix. Any pronounced

change in direction should be made on stable material.

Rolling hot bituminous mix is done in the following

order:

1.

2.

3.

4.

5.

Transverse joints

Longitudinal joints (when adjoining a pre-

viously placed lane)

Breakdown or initial rolling

Intermediate or second rolling

Finish rolling

As a guide, longitudinal joint and edge rolling

should be performed directly behind the paver;

breakdown rolling less than 200 feet behind the paver;

intermediate rolling 200 feet or more behind the

breakdown rolling; and finish rolling as soon as possible

behind the breakdown rolling.

Transverse Joints

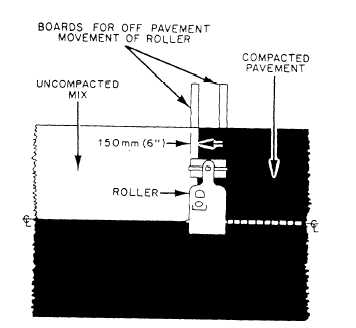

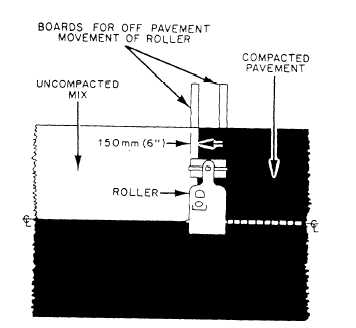

When a transverse joint is placed next to an

adjoining lane, the first pass is made with a steel-

wheeled roller moving along the longitudinal joint for a

short distance. The surface is then straightedge and

corrections made if necessary. The joint is then rolled

transversely with all except 6 inches of the wheel width

on the previously laid material (fig. 11-49). This

operation should be repeated with successive passes

Figure 11-49.-Rolling a transverse joint.

covering 6 to 8 inches of fresh material until the entire

width of a roll is on the new mix.

During transverse rolling, boards of proper

thickness should be placed at the edge of the pavement

to provide the roller a surface to drive on once it passes

the edge of the hot bituminous mat. If boards are not

used, the transverse rolling must stop 6 to 8 inches short

of the outside edge in order to prevent damage to the

edge. The outside edge then must be rolled out during

longitudinal rolling.

Longitudinal Joints

Longitudinal joints should be rolled directly behind

the paving operation, Only 4 to 6 inches of the roller

width should ride on the newly placed mix (fig. 11-50).

The rest of the roller should ride on the previously

compacted side of the joint. With each subsequent pass,

more and more of the roller width is placed on the mix

until the entire width of the roller is on the newly placed

mat.

When rolling a longitudinal joint with a vibratory

roller, the roller drum extends only 4 to 6 inches on the

previously compacted lane with the rest of the drum

width riding on the newly placed mat. The roller

continues to roll along this line until a thoroughly

compacted, neat joint is obtained.

Longitudinal

cold joint.

joints can be categorized as a hot or

11-26