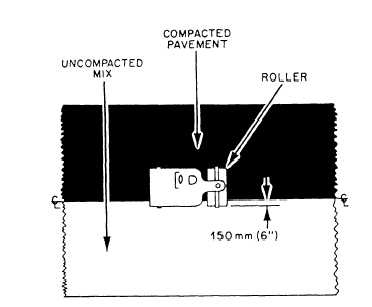

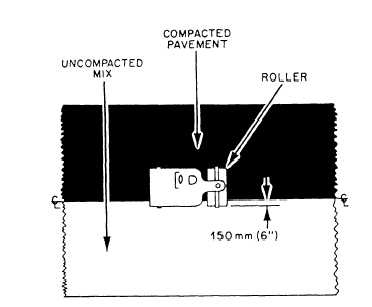

Figure 11-50.—Rolling a longitudinal joint.

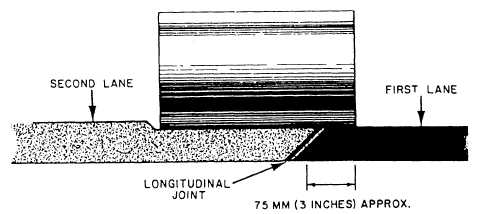

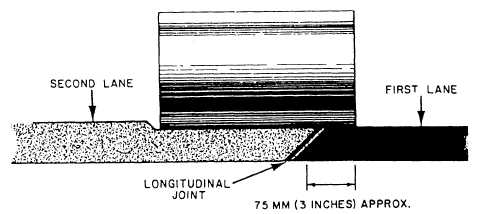

HOT JOINTS.— A hot joint is a joint between two

lanes of bituminous mix placed at approximately the

same time by pavers working in echelon. This type of

laydown produces the best longitudinal joint, because

both lanes are at, or near, the same temperature when

rolled. The material compacts into a single mass under

the roller, resulting with little or no difference in density

between the two lanes. When you are paving in echelon,

the breakdown roller following the lead paver leaves a

3- to 6-inch unrolled edge that the second paver follows.

The second paver and roller should stay as close as

possible to the first paver to ensure a uniform density is

obtained across the joint. The roller following the

second paver compacts the hot joint on its first pass

(fig. 11-51).

COLD JOINTS.— A cold joint is a joint between

two lanes, one of which has cooled overnight or longer

before the adjoining lane is placed. Because of the

difference in temperature between the two lanes, there

is a difference in density between the two sides of the

joint. The longitudinal joint should be rolled directly

behind the paver.

Breakdown Rolling

Breakdown rolling may be accomplished with static

or vibratory steel-wheel rollers. Breakdown rolling

should start on the low side of the hot bituminous mat,

which is usually the outside of the lane being paved, and

progress toward the high side. The reason for this is that

hot bituminous mixtures tend to migrate towards the low

side of the mat under the action of the roller. If rolling

is started on the high side, this migration is much more

pronounced than if the rolling progresses from the low

side. When adjoining lanes are placed, the same rolling

procedure should be followed, but only after com-

paction of the longitudinal joint.

A rolling pattern that provides the most uniform

coverage of the lane being paved should be used. Rollers

vary in width, and a single recommended pattern that

applies to all rollers is impractical. For this reason, the

best rolling pattern for each roller being used should be

worked out and followed to obtain the most uniform

compaction across the lane.

The rolling pattern not only includes the number of

passes but also the location of the first pass, the sequence

of succeeding passes, and the overlapping between

passes. Rolling speed should not exceed 3 mph. In

addition, sharp turns and quick starts or stops are to be

avoided.

For thin lifts (a lift of less than 2 inches compacted

thickness), a recommended rolling pattern for static

Figure 11-51.—Rolling a hot longitudinal joint.

11-27