fluids at rest or in motion, while inertia and

friction are dynamic factors that apply only to

fluids in motion. The mathematical sum of

gravity, applied force, and atmospheric pressure

is the static pressure obtained at any one point

in a fluid at any given time. Static pressure exists

in addition to any dynamic factors that may also

be present at the same time.

Remember, Pascal’s law states that a pressure

set up in a fluid acts equally in all directions and

at right angles to the containing surfaces. This

covers the situation only for fluids at rest or

practically at rest. It is true only for the factors

making up static head. Obviously, when velocity

becomes a factor it must have a direction, and

as previously explained, the force related to the

velocity must also have a direction, so that

Pascal’s law alone does not apply to the dynamic

factors of fluid power.

The dynamic factors of inertia and friction are

related to the static factors. Velocity head and

friction head are obtained at the expense of static

head. However, a portion of the velocity head can

always be reconverted to static head. Force, which

can be produced by pressure or head when dealing

with fluids, is necessary to start a body moving

if it is at rest, and is present in some form when

the motion of the body is arrested; therefore,

whenever a fluid is given velocity, some part of

its original static head is used to impart this

velocity, which then exists as velocity head.

BERNOULLI’S PRINCIPLE

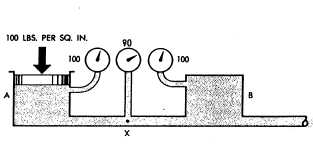

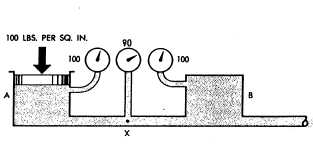

Consider the system illustrated in figure 2-18.

Chamber A is under pressure and is connected by

a tube to chamber B, which is also under pressure.

The pressure in chamber A is static pressure of

100 psi. The pressure at some point (X) along the

connecting tube consists of a velocity pressure of

Figure 2-18.—Relation of static and dynamic factors—

Bernoulli’s principle.

10 psi exerted in a direction parallel to the line

of flow, plus the unused static pressure of 90 psi,

which still obeys Pascal’s law and operates equally

in all directions. As the fluid enters chamber B

it is slowed down, and its velocity is changed back

to pressure. The force required to absorb its

inertia equals the force required to start the fluid

moving originally, so that the static pressure in

chamber B is equal to that in chamber A.

This situation (fig. 2-18) disregards friction;

therefore, it would not be encountered in actual

practice. Force or head is also required to

overcome friction but, unlike inertia effect, this

force cannot be recovered again, although the

energy represented still exists somewhere as heat.

Therefore, in an actual system the pressure in

chamber B would be less than in chamber A by

the amount of pressure used in overcoming

friction along the way.

At all points in a system the static pressure is

always the original static pressure, less any velocity

head at the point in question and less the friction

head consumed in reaching that point. Since both

the velocity head and the friction head represent

energy that came from the original static head,

and since energy cannot be destroyed, the sum of

the static head, the velocity head, and the friction

head at any point in the system must add up to

the original static head. This is known as

Bernoulli's principle, which states: For the

horizontal flow of fluid through a tube, the sum

of the pressure and the kinetic energy per unit

volume of the fluid is constant. This principle

governs the relations of the static and dynamic

factors concerning fluids, while Pascal’s law states

the manner in which the static factors behave

when taken by themselves.

MINIMIZING FRICTION

Fluid power equipment is designed to reduce

friction to the lowest possible level. Volume and

velocity of flow are made the subject of careful

study. The proper fluid for the system is chosen.

Clean, smooth pipe of the best dimensions for the

particular conditions is used, and it is installed

along as direct a route as possible. Sharp bends

and sudden changes in cross-sectional areas are

avoided. Valves, gauges, and other components

are designed to interrupt flow as little as possible.

Careful thought is given to the size and shape of

the openings. The systems are designed so they

2-14