CHAPTER 9

RESERVOIRS, STRAINERS, FILTERS,

AND ACCUMULATORS

Fluid power systems must have a sufficient

and continuous supply of uncontaminated fluid

to operate efficiently. As stated in chapter 3 and

emphasized throughout this manual, the fluid

must be kept free of all foreign matter.

This chapter covers hydraulic reservoirs,

various types of strainers and filters, and

accumulators installed in fluid power systems.

RESERVOIRS

A hydraulic system must have a reserve of

fluid in addition to that contained in the pumps,

actuators, pipes, and other components of the

system. This reserve fluid must be readily available

to make up losses of fluid from the system, to

make up for compression of the fluid under

pressure, and to compensate for the loss of

volume as the fluid cools. This extra fluid is

contained in a tank usually called a reservoir. A

reservoir may sometimes be referred to as a sump

tank, service tank, operating tank, supply tank,

or base tank.

In addition to providing storage for the reserve

fluid needed for the system, the reservoir acts as

a radiator for dissipating heat from the fluid and

as a settling tank where heavy particles of

contamination may settle out of the fluid and

remain harmlessly on the bottom until removed

by cleaning or flushing of the reservoir. Also, the

reservoir allows entrained air to separate from the

fluid.

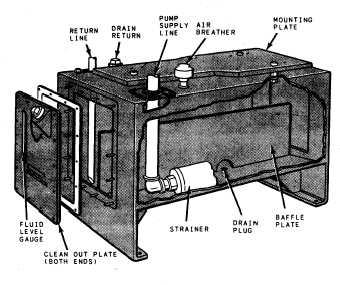

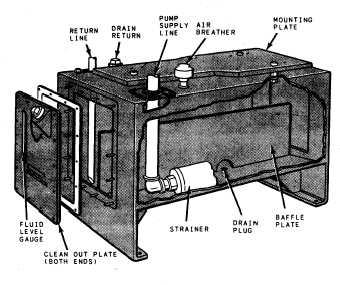

Most reservoirs have a capped opening for

filling, an air vent, an oil level indicator or dip

stick, a return line connection, a pump inlet or

suction line connection, a drain line connection,

and a drain plug (fig. 9-1). The inside of the

reservoir generally will have baffles to prevent

excessive sloshing of the fluid and to put a

partition between the fluid return line and the

pump suction or inlet line. The partition forces

the returning fluid to travel farther around the

tank before being drawn back into the active

Figure 9-1.—Nonpressurized reservoir (ground or ship

installation).

system through the pump inlet line. This aids in

settling the contamination and separating the air

from the fluid.

Large reservoirs are desirable for cooling. A

large reservoir also reduces recirculation which

helps settle contamination and separate air. As

a ‘‘thumb rule,” the ideal reservoir should be two

to three times the pump output per minute.

However, due to space limitations in mobile and

aerospace systems, the benefits of a large reservoir

may have to be sacrificed. But, they must be large

enough to accommodate thermal expansion of the

fluid and changes in fluid level due to system

operation. Reservoirs are of two general types—

nonpressurized and pressurized.

NONPRESSURIZED RESERVOIRS

Hydraulic systems designed to operate

equipment at or near sea level are normally

equipped with nonpressurized reservoirs. This

includes the hydraulic systems of ground and ship

9-1