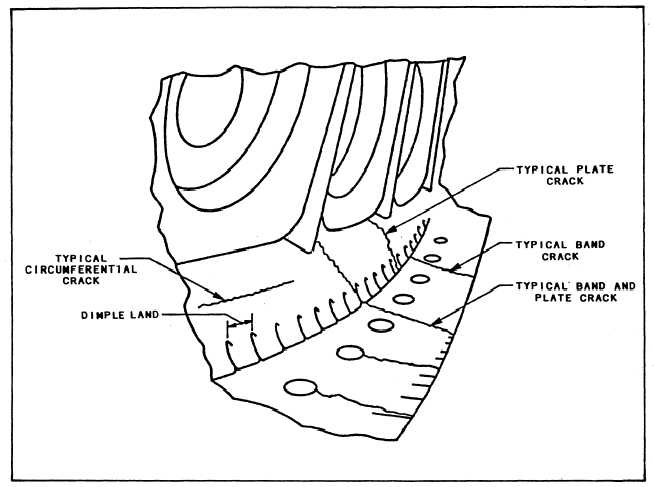

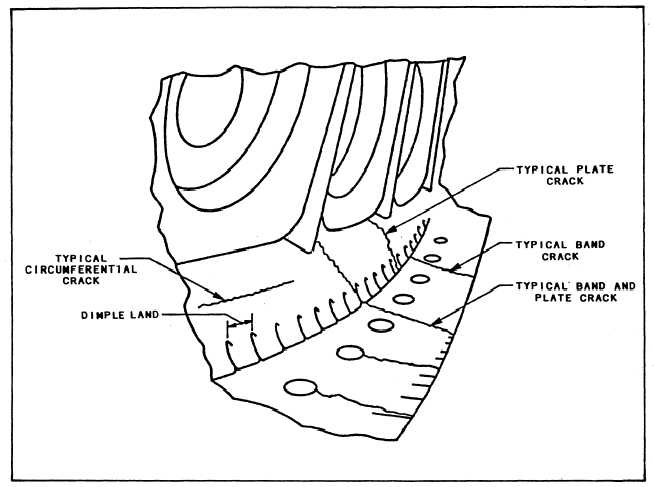

Figure 2-19.—Combustion liner dome band and plate cracks.

Cracking (fig. 2-19) in the dome band area occurs

at relatively low operating time. Record the number of

cracks and their relationship to one another. Indicate if

these cracks are parallel, T-shaped, circumferential or

angled to connect and separate part of the band, and so

forth.

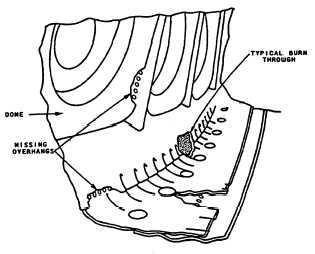

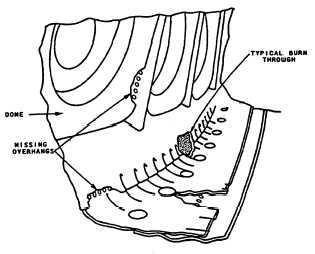

All the missing metal areas or burn-throughs (fig.

2-20) must be recorded. For the dome bands, estimate

the magnitude by the number or partial/circumferential

span of the dimples and axially by percent of span of the

band overhang to the trumpet. Record the trumpet areas

of burn-away and burn-through of the dome plate

around the swirl cups. Burn-through in the combustor

dome will reduce cooling flow to the HP turbine vanes.

Monitor the HP turbine vane condition as burn-through

progresses.

Igniter Tubes and Ferrules.— Inspect the two

igniter locations (fig. 2-21) for the condition of the weld

at the cutaway of the trumpet and the dome band. The

ferrules are visible from these ports. Record the

condition for evidence of cracking, 10SS of ferrule metal,

or both. Cracking from the igniter tube aft to the panel

overhang is common.

Figure 2-20.—Combustion liner dome bums and missing

metal.

2-16