trailing edge). These curled tips are usually smooth in

the bend area of the airfoil distortion. However, you

should inspect the area at the change in normal airfoil

for tears or cracks. When you report tip curl, estimate

the percent of the chord length, the number of blades

with curl, and the condition of the adjacent airfoil area.

Record any evidence of impact and inspect for the origin

of the impact. Always look at the adjacent blades for

evidence of tip clang.

Missing Metal.— Missing metal from compressor

rotor blade airfoils is a result of the progression of

cracked or tom airfoils that release part of the airfoil into

the flow path. Crack propagation in the root fillet area

can result in the separation of the entire blade. Severe

FOD or DOD may result in several random rotor and

stator airfoils with missing metal. The inspection report

should include the stage, the number of blades with

missing metal, the amount, and the location on the

airfoil. Estimate the percent of chord, the span of the

airfoil that is missing metal, and the condition of the

remaining airfoil.

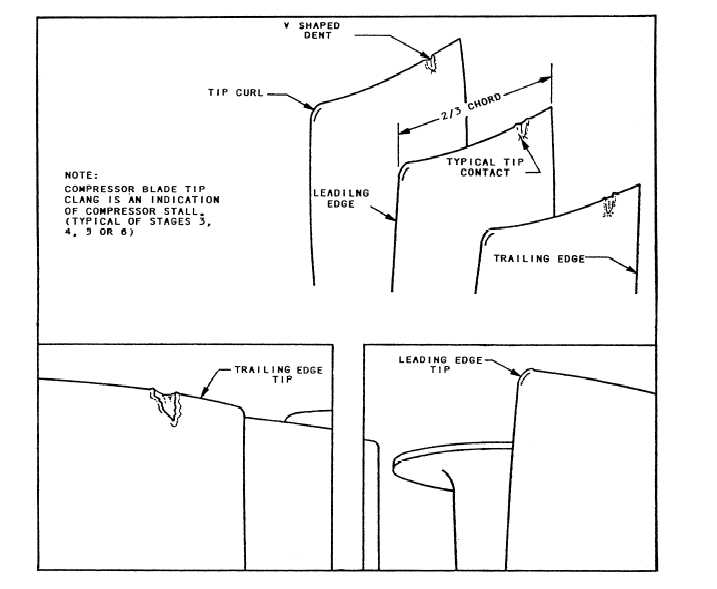

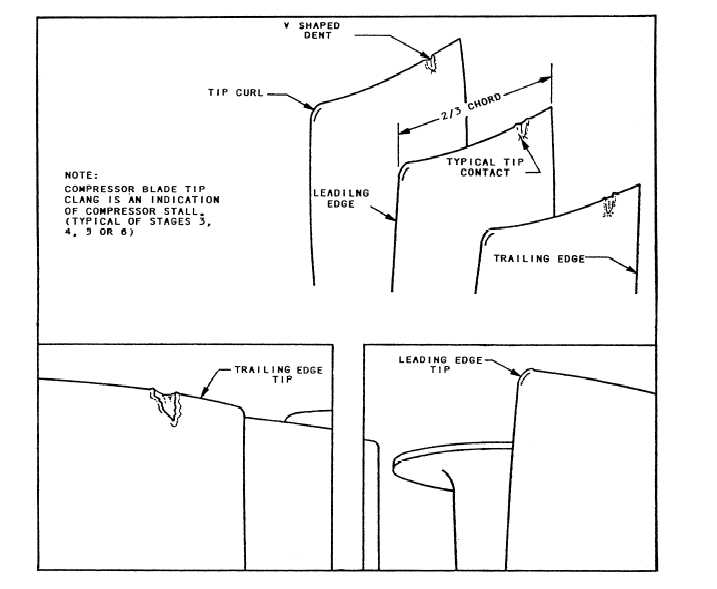

Airfoil Surface Defects.— Surface defects are the

result of object damage or adjacent blade interference

(tip clang). Impacts in the center section of the airfoil

are not common. Tip clang damage is the result of a

blade leading edge tip contacting the adjacent blade tip

at approximately one-third of the chord length forward

of the trailing edge on the low-pressure (convex) side of

the blade (fig. 2-13). This is the result of compressor

stall and is observed in stages 3 through 6. You should

report any observed defect on the airfoil surfaces in the

inspection record.

Your report should contain

Figure 2-13.—Compressor rotor blade tip clang damage.

2-12