information relative to the stage, location on the blade

(estimate the percent of chord and span), and the

condition of the surrounding airfoil. You do not have to

record the appearance of the defect (sharpness and

contour). Compressor stall is one of the worst things

that can happen to an engine. tip clang damage is

difficult to spot and gives the appearance of minor

damage. The V-shaped notch on the top of a blade

caused by tip clang is only an indicator; it in itself is not

the damage. The damage is at the blade root and

normally cannot be seen.

If a blade has been

overstressed, it must be replaced.

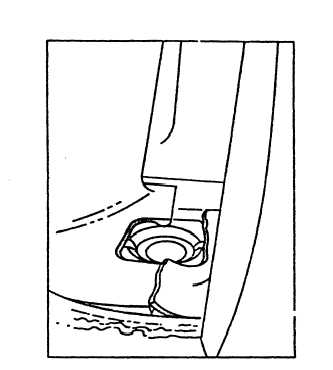

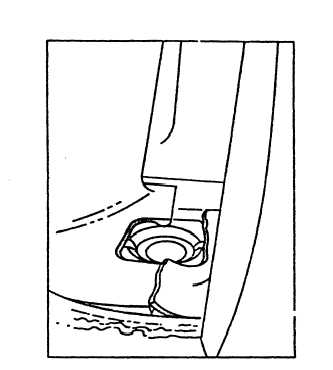

Platform Distortion.— Compressor blade platform

fretting or shingling (fig. 2-14) can be observed on some

after stage blades. These distortions are the overlapping

of one blade platform mating edge with the adjacent

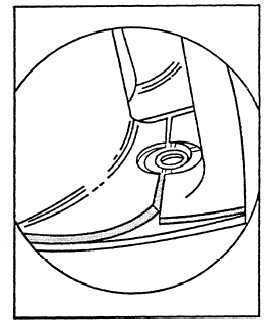

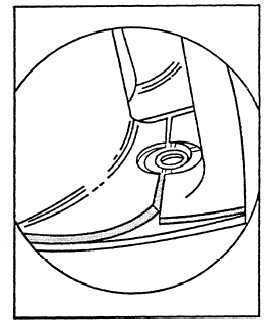

platform edge. When shingling is found, the platforms

will be distorted and bowed (fig. 2-15). When the

platforms are shingled, only the locking lug blades will

exhibit this defect. Monitor this condition to see if a

platform crack develops. Also look for missing pieces

around the locking lugs. You must report and record any

cracks in the platform. Be sure you have included the

following information:

The stage

The number of blades

Figure 2-14.—Platform fretting or shingling.

Figure 2-15.—Platform bowing.

The spacing of the blade numbers separating the

shingled blade platforms

The platform gap observation (estimate gap as

percent of circumferential span of the platform)

The condition of the shingled edge (bent, fretted,

or stepped as per table 2-1)

Midspan

Shroud

Wear.—

Some stage 1

compressor blades show wear at the mating surfaces of

the midspan damper shrouds. (See figs. 2-16 and 2-17.)

Wearing of the tungsten-carbide wear coat causes the

mating face contour to change from a straight line to a

stepped line.

This occurs at the after edge of the

clockwise blade midspan (trailing edge) and the forward

edge of the counterclockwise blade midspan shroud

(leading edge). In the step area, some metal maybe

turned or protruding from the midspan shroud mating

line (mushrooming). This protrusion is indicative of

wear-through. A missing pad on one face would initiate

an accelerated failure of the mating surfaces.

BLADE DEPOSITS.— Compressor blades and

stator vanes exhibit varying degrees of cleanliness.

Variables such as air-inlet configuration, ambient

atmospheric conditions, and air contaminants

(chemicals, salt, dirt, water, and so forth) all tend to

affect the surface condition of the compressor rotor and

stator blades.

A l u m i n u m D e p o s i t s . — Two areas in the

compressor assembly are coated with aluminum, the

2-13