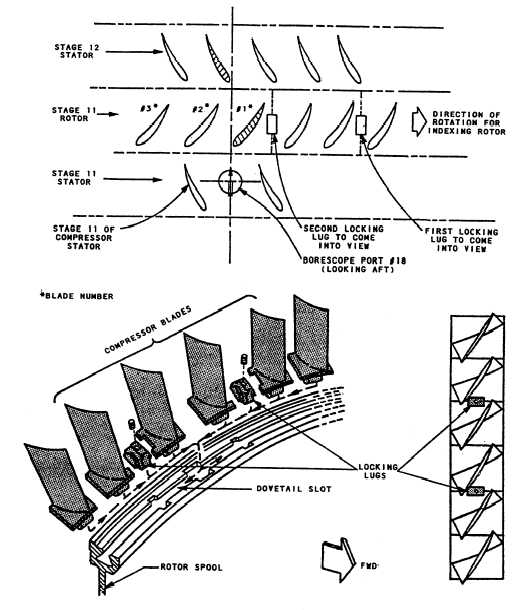

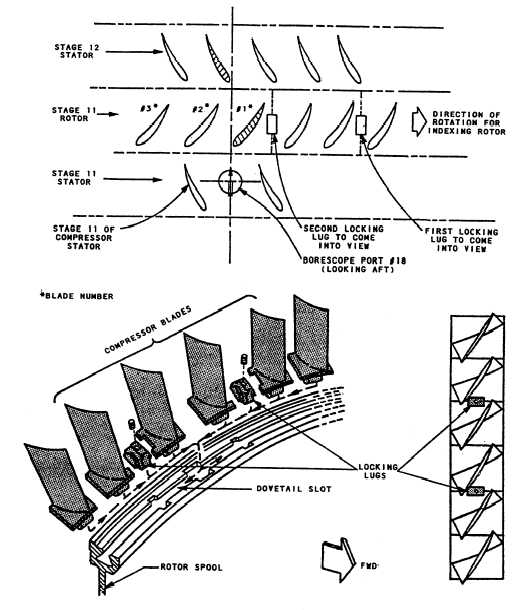

Figure 2-10.—Zero indexing the compressor rotor.

damage. Beginning with the third stage, if a slight tilting

of the blade or raising of the blade platform is observed,

suspect blade root failure.

This condition requires

suspended engine operation until the condition has been

evaluated

COMPRESSOR DAMAGE.— In tie following

paragraphs, redescribe some of the damage you may

find during an engine inspection. You can find the

condition codes used to describe engine damage in

foldout table 2-1.

Airfoil

and

Tip

Cracks.—

Cracks

in

the

compressor hardware are difficult to detect because they

are tight and shallow in depth. You can miss these subtle

defects because of deteriorated borescope optics or if

you rotate the rotor too fast. You should record all crack

information relative to the stage, area, magnitude,

direction, and adjacent blade condition.

Cracked Dovetail.— A cracked dovetail of a blade

may lead to blade loss. The location of the blade will

determine the extent of engine damage. Before the

actual catastrophic failure of the blade, the separated

crack in the dovetail will be evident by a leaning blade

platform. You can find this fault by using the borescope

to inspect each blade platform. The leaning blade

platform will be higher than the adjacent nonleaning

blades.e A “leaner” is a blade that has a crack on the aft

2-10