viewed through wide angle probe No. 2. When

circumferential cracking is observed, record the band

number and the span of the cracking relative to the

number of cooling/dilution holes. Use the diameter

of the cooling holes as a comparative measurement

gauge.

Axial Cracks. — Axial cracking usually starts at

band No. 3 on the inner liners and propagates aft and

forward. As operating time is accrued, these axial

panel cracks grow into three-legged cracks as seen in

figure 2-23. The edges of these cracks will separate

and the corners will lift into the flow path. Inspect the

areas aft and forward of these cracks, recording the

axially separated cracks that show a tendency to grow

together.

DOD is the primary cause of damage to the HP

nozzle and turbine rotor elements. It is caused by pieces

from the combustor liners cracking out of the panel

overhangs and impacting with the rotating turbine

elements. The most serious problem is the separation of

a large section of liner that could cause significant

damage. This usually occurs as a result of axial and

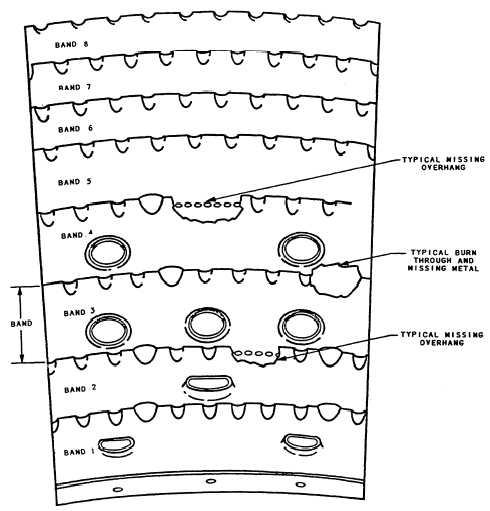

circumferential cracks growing together as shown in

figure 2-24. It is important to record the damage to

adjacent areas of about 5 inches to either side of the

damaged area.

These areas can grow together and

l i b e r a t e l a r g e p i e c e s o f m a t e r i a l .

T h e s e

circumferentially spaced, cracked areas are usually

separated at every other fuel nozzle spacing along with

axial color streaking.

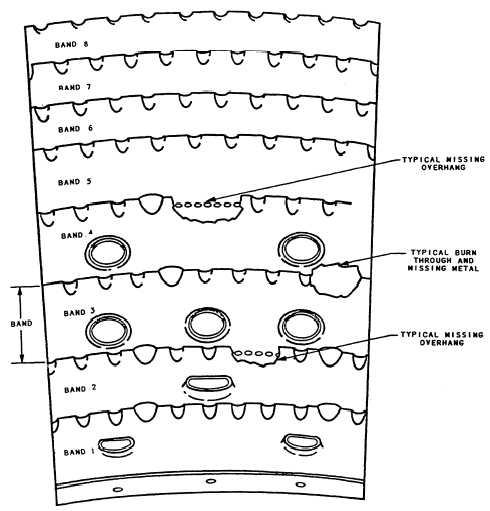

Missing Metal and Burn-Through.— Inspect for

the loss of metal at the panel overhang and the area

between dimples (fig. 2-25). Bum-through of the liners

is not common. What is common are the bluish-black

slag areas that show roughness and appear to be

oxidized. Inspect these areas carefully for T cracks

because they will propagate and open up.

Figure 2-25.—Inner/outer liner burns and missing metal.

2-19