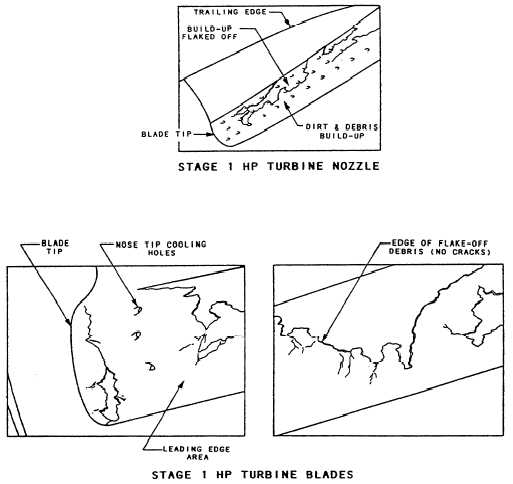

Figure 2-26.—HP turbine blade flaking and buildup.

Record the magnitude and span location relative to the

number of gill holes spanned. Estimate the out of

contour as percent of the leading edge frontal area width

or relative to the lateral spanning of the leading edge

cooling hole rows.

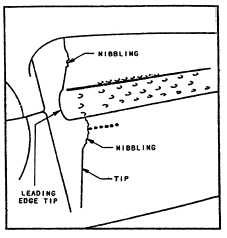

Blade Tip Nibbling.— The HP turbine rotor stage

1 blade tip nibbling is associated with hot running

engines. Momentary overtemperature operation (such

as experienced during compressor stalls) has exhibited

this type of deterioration. This area of the blade is above

the tip cap and located about two-thirds of the chord aft

from the leading edge. Figure 2-27 shows a typical

“nibbled tip” as a result of a severe stall.

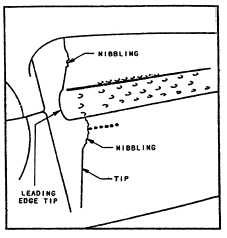

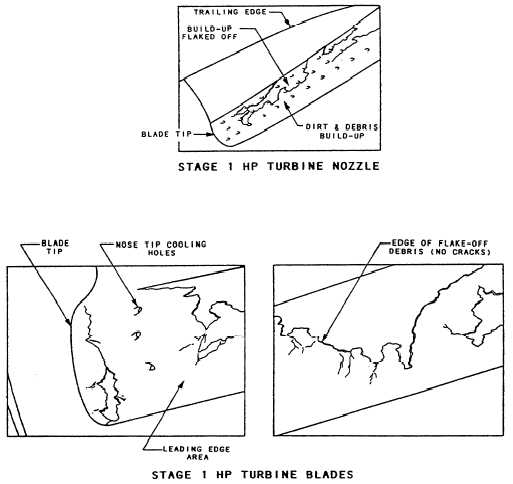

Blade Leading Edge Impact Damage.— Figures

2-28 and 2-29 show an impacted and distorted leading

edge of a stage 1 HP turbine rotor blade. (Note the

cracking condition leading from the impact area into the

airfoil surface.) The critical part of this type of damage

is the axial or chord wire cracking. If this cracking

progresses from the impacted damaged area into the

Figure 2-27.—HP turbine blade tip nibbling.

convex or concave airfoil surface, the damage can be

severe.

HP Turbine Blade Coating Failure.— The HP

turbine protective coating is the key factor in the service

2-22