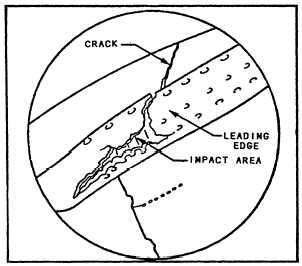

Figure 2-28.—HP turbine blade impact damage.

life of an LM2500 GTE. The combined effect of film

cooling and protective coating will extend the service

life. Coatings are thinly and uniformly applied by a

vacuum film deposition process. Coatings do not

usually cause problems by chipping, peeling, or flaking.

The normal failure mode is usually by pitting, rub off,

or nicks and scratches. Occasionally a bubble will occur

in the surface coating during the coating process. If a

bubble occurs, it will be tested at the coating facility to

ensure that it cannot be rubbed off the surface. These

bubble imperfections pose no problem to the engine. If

the bubble area of the coating fails, you should monitor

that area to determine any further deterioration.

Development and testing of new coatings that are highly

resistant to corrosion and erosion are in progress. The

present blade coating for single shank HP turbines is

designated BC23. However, twin shank HP turbine

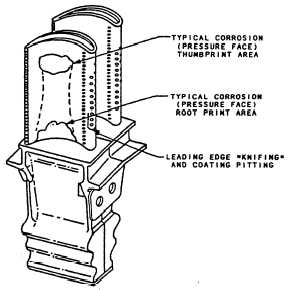

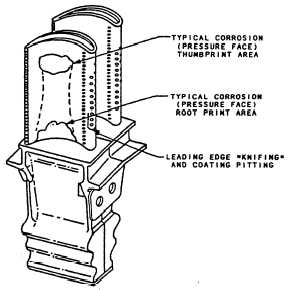

Figure 2-30.—HP turbine rotor stage 1 blade—areas of severe

corrosion after extensive operating time.

blading presently have blade coating BC21. As they

become serviceable by an area Naval Aviation Depot

(NADEP) these blades will be replaced with blades

coated with BC23. Use of these newer blade coatings

can significantly extend blade service life.

HP TURBINE BLADE FAILURE MODES.—

Failures that you may observe during a borescope

inspection include the following types:

Corrosion of the coating. This appears as pitting

of the coating primarily in the 80-percent span

midchord region of the concave airfoil

(thumbprint) side and the 20-percent span

midchord region (root print) (fig. 2-30). This

corrosion/erosion has not been found on blades

coated with BC23.

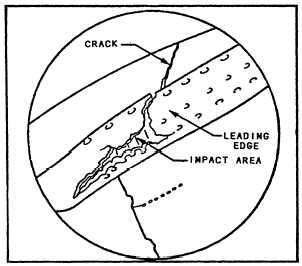

Figure 2-29.—HP turbine leading edge impact damage.

2-23