Distributing and balancing the forces and

figure 10-19. Thus, a return to an original shape

stresses produced by weld shrinkage by

and size is possible only when a part is free to

special welding techniques and sequences

expand and contract freely and without restraint.

Forcibly restraining the parts being joined

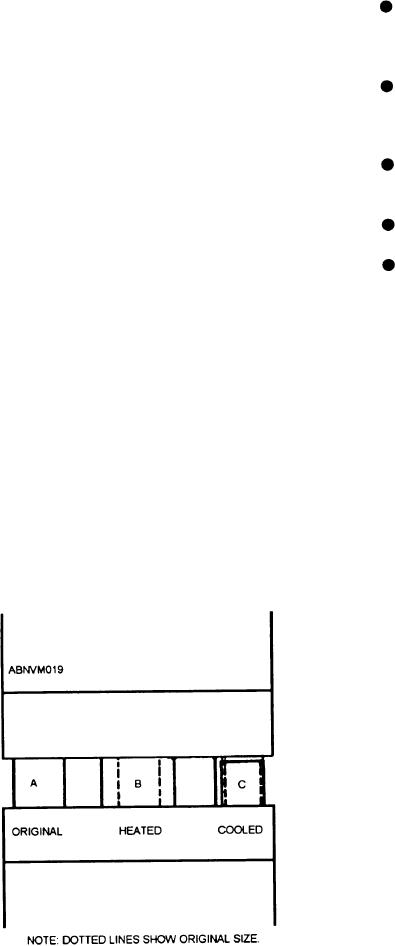

If a bar is heated over a small area, the

from movement during welding by suitable

expansion will be local and uneven. The mass of

jigs and fixtures

surrounding metal will not expand, and tends to

prevent expansion of the heated metal in all

directions except upon the surface. Consequently,

Selecting the joint and the geometry of the

when the yield point has been reached, the metal

joint selected

becomes permanently deformed. When the bar

cools, it does not return to its original form, and

Selecting the welding process

distortion results.

Selecting the weld joint bead procedure

The factors governing distortion are the

resistance of the structure to the free contraction of

Preheating involves raising the temperature of

the weld metal; the temperature gradient, which is

the base metal or a section of the base metal above

determined by the rate at which heat is applied and

the ambient temperature before welding. Preheat

the rate at which heat is conducted away from its

temperatures may vary from as low as 60F to as

point of application; the coefficient of expansion of

high as 600F for highly hardenable steels and

the metal, which determines the total amount of

1200F for ductile cast iron.

plastic movement; and the yield strengths of the

base and weld metal, which limit the residual forces

Preheating is a very effective means of reducing

that can exist within the structure. Generally

weld metal and base metal cracking. Preheating

speaking, there are six basic means of controlling

may improve weldability generally, but has two

distortion:

major beneficial effects: it retards the cooling rates

in the weld metal and heat-affected base metal, and

Stretching the metal, preferably while still

it reduces the magnitude of shrinkage stresses.

hot, by a series of hammer blows (peening)

However, when you are welding quenched or

age-hardened materials, the effects of preheating

can be detrimental unless they are controlled within

allowable limits.

In many operations, the temperature to which

the base metal is heated must be carefully

controlled. The best means of control is to heat the

part in a furnace held at the desired temperature, by

electric induction coils, or by electric resistance

heating blankets. In these methods, temperature

indicators are attached to the part being preheated.

Figure 10-20 shows electric induction coils set up for

preheating pipe prior to welding.

W h e n using the oxyacetylene torch for

preheating, it is important to prevent localized

overheating and deposits of incomplete combustion

of gases on the surfaces of the joints of areas to be

welded. Temperature-indicating crayons that melt

at known temperatures are used for measuring the

temperature of the preheated part.

Figure 10-19.--Dimensional changes due to restrained

expansion and unrestrained contraction.

10-18