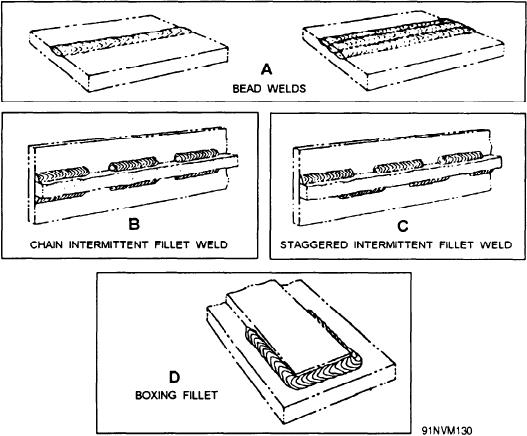

Several types of bead and fillet welds are

very-low-pressure tanks use corner joints because

illustrated in figure 7-3. Usually a BEAD WELD

the root of the weld is in tension under load. The

(fig. 7-3, view A) is made by depositing filler metal

tee joint forms the shape of the letter T. Tee joints

in a single direction on an unbroken surface.

are used in many types of metal structures. The tee

However, it is also possible to make a bead without

joint distributes stress more evenly throughout the

adding filler metal. In this case, the heat is applied

structure.

and moved along steadily in one direction so that a

The LAP joint is used to join overlapping

molten puddle is formed in the base metal. Bead

welds are used principally on butt joints and as a

members of a structure. The joint area of a lap

way of building up surfaces. The cross section of a

joint is between the parallel surfaces of the joint

bead weld usually has an oval shape.

members. Lap joints are often used in torch brazing

processes where capillary action draws filler metal

A FILLET WELD is triangular in cross section.

into the space between the hot surfaces. They are

It joins two surfaces that are at approximately right

also used in many resistance welding processes,

angles to each other. Fillets are used to weld lap,

especially in sheet metal structures fabricated with

tee, and corner joints. As shown in views B, C, and

spot welds.

D of figure 7-3, some variations of the fillet weld

are chain intermittent, staggered intermittent, and

TYPES OF WELDS

boxing.

The types of welds most commonly used aboard

A TACK WELD is a short weld deposit made

ship are bead welds, fillet welds, tack welds, groove

to temporarily hold the parts to be joined in proper

welds, plug welds, slot welds, spot welds, and seam

alignment for final welding. The sizes of tack welds

welds. Another term that you will hear quite often

are usually not specified, but they must not exceed

is SEAL WELD. This term does not actually refer

1 inch in length, and they must be as small as can

to any one type of weld; rather, it is any weld that

be made, consistent with the size of the electrode

is used primarily to obtain tightness.

being used. Tack welds must be incorporated into

Figure 7-3.--Bead and fillet welds.

7-6