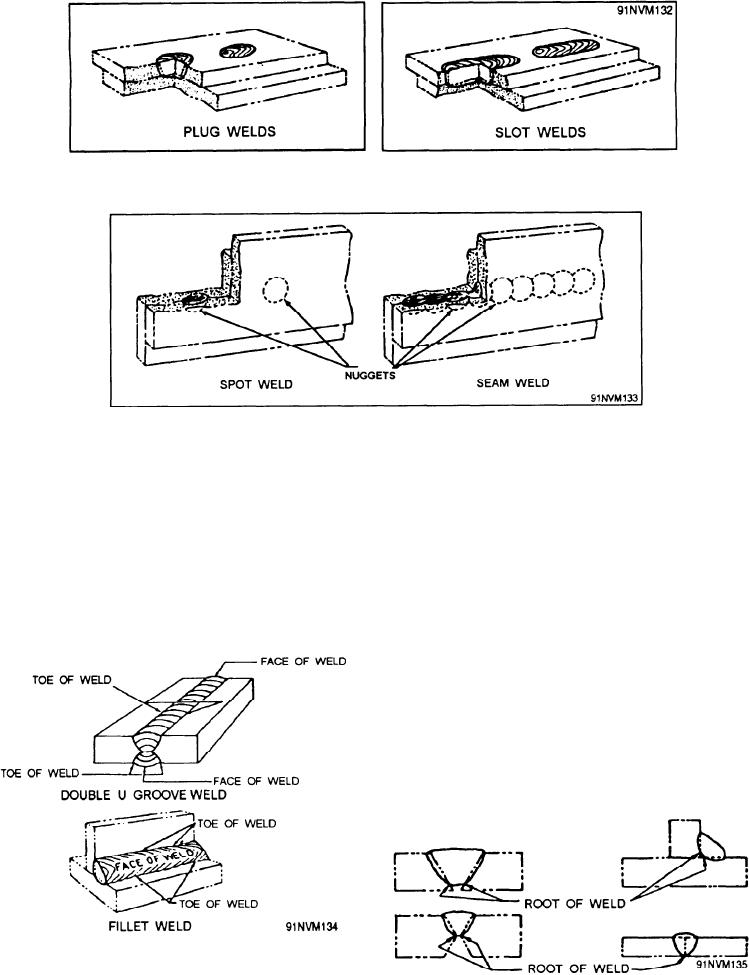

Figure 7-5.--Plug and slot welds.

Figure 7-6.--Spot weld and seam welds.

More commonly, however, seam welds are made

overlap. The size and shape of the weld (often

with a wheel-type electrode.

called the nugget) are determined by the size and

shape of the electrode tips used in the welding

PARTS OF WELDS

machine. A seam weld is very much like a spot

weld and may, in fact, be made as a series of

You should be familiar with the terms used to

overlapping spot welds, as shown in figure 7-6.

describe the parts of welds. Figure 7-7 illustrates

the face and the toe on groove and fillet welds. The

FACE is the exposed surface, on the side from

which the weld was made, of a weld made by a gas

or arc welding process. The TOE is the junction

between the face of the weld and the base metal.

The ROOT of a weld includes the points at

which the bottom of the weld intersects the base

metal surfaces, as seen in cross section. Figure 7-8

illustrates weld roots.

Figure 7-7.--Face and toe of groove and fillet welds.

Figure 7-8.--Weld roots.

7-8