the finished weld. Cracked or broken tack welds

plates that are not otherwise accessible for welding.

must be chipped or ground out before the joint is

A plug weld is a circular weld made through one

member of a lap or tee joint to join that member to

finally welded.

another. The plug weld may or may not be through

a hole punched or cut in the first member. If a hole

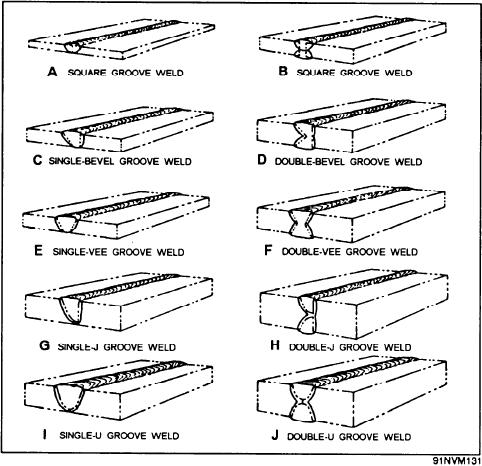

GROOVE WELDS are made in a specially

prepared groove between two members to be joined.

is used in the first member, the plug weld may fill it

While the edge of a vertical plate of a tee joint is

completely or it may fill it only partially. A slot

sometimes beveled for welding, grooves are most

weld is similar to a plug weld, except that an

frequently used for butt joints in plate and pipe

elongated hole is made in the first member of the

work. Standard grooves for plates joined with butt

joint. The hole may be completely or partially filled

joints are illustrated in figure 7-4. Groove welds are

with weld metal. Slot welds are often used to join

designed to provide the required strength with a

one plate to the surface of another plate, and for

minimum amount of filler metal. Plate edges may

other purposes where a fillet weld would not be

be prepared for groove welding by shearing,

economical or would not be a good design.

machining, chipping, grinding, flame cutting, or

Incidentally, a fillet weld made at the intersection of

flame grooving, depending on the metal. The

the edge of a slot and the exposed surface of the

selection of a particular groove design is governed

joining member is considered a fillet weld, NOT a

by the thickness of the plate to be welded, the

slot weld.

adaptability of the design to the structure, and the

accessibility of the joint for welding. For example,

S P O T WELDS and SEAM WELDS are

a joint that can be welded from only one side

common types of resistance welds. These welds are

requires a different groove design than a joint that

shown in figure 7-6.

In resistance welding,

is accessible from both sides.

coalescence is produced by a combination of

pressure and the heat obtained from the resistance

P L U G WELDS and SLOT WELDS, as

of the base metal to the flow of an electric current.

illustrated in figure 7-5, are used to join overlapping

A spot weld is used only when the parts of the joint

Figure 7-4.--Standard groove welds.

7-7