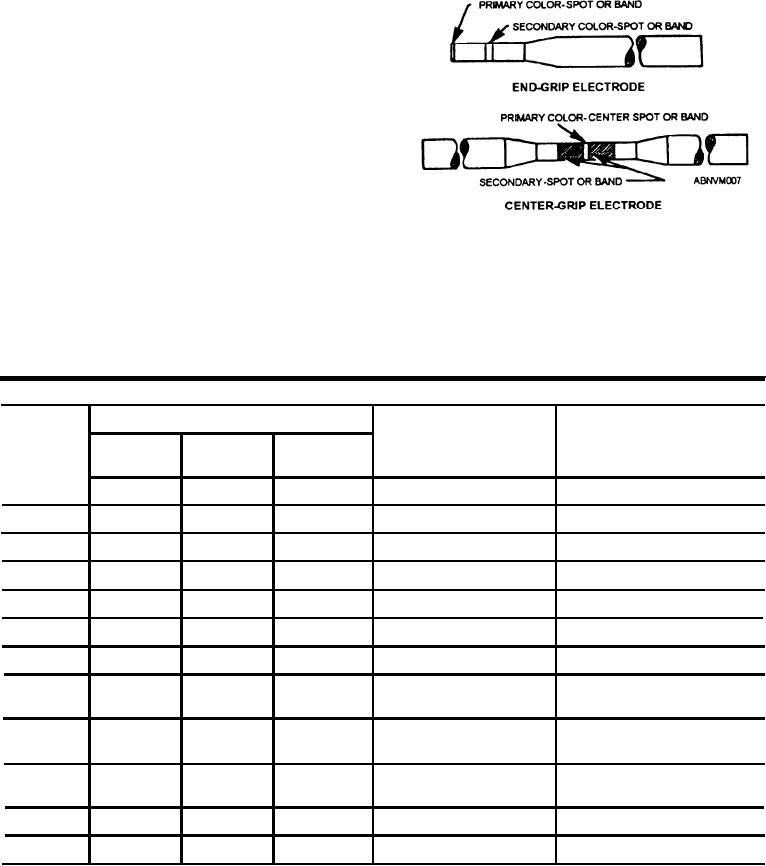

In addition to the electrode classification

numbers, iron and steel electrodes may be identified

by a standard color code set up by the National

Electrical Manufacturers' Association (NEMA).

This method of electrode identification uses a

two-color system consisting of a primary color

located on the end of the electrode and a secondary

color located near the top end of the electrode.

Figure 10-7 shows the location of the primary and

s e c o n d a r y on the end grip and center grip

electrodes. Part of the electrode color identification

table produced by NEMA is reproduced in table

10-2.

PREPARATIONS FOR WELDING

Before beginning to weld, be sure you have all

the required equipment for welding and all the

equipment needed for your personal protection. Be

Figure 10-7.--Electrode color markings.

sure the welding machine is in good condition. Do

Table 10-2.--Color Markings For Electrode Identification

Primary colors

Mild steel and low alloys (See Note I)

Special purpose

Hard surfacing (See Note II)

Spot or

Horizontal

Flat position

All position

secondary

fillets & flat

only

color

Blue

White

Orange

Brown

No color

0.40-0.70% Carbon

Mild steel for cast iron

E6010

E6020

E6030

No color

0.90-1.10% Carbon

E6011

Blue

Brinell 200 min

Cast iron for cast iron

E6012

White

Brinell 300 min

051.0% Ni

Brown

E6013

Brinell 400 min

E7010

E7020

E7030

2.0-3.0% Ni

Green

Brinell 500 min

12.0-14.0% Mn

E7011

Red

Brinell 600 min

E8010

E8020

E8030

Ni Mn

Yellow

E8011

Brinell 700 min

E9010

E9020

E9030

Ni Cr MO

Black

E9011

Ni Cr Cu

El0020

El0030

Orange

El0010

E10011

Violet

Gray

Note I:

Electrodes listed with prefix letter are AWS designated grades.

Hardness shall be determined as follows:

Note II:

(a) Use a base plate of mild steel 5" square 1" thick.

(b) Use 3/16" electrode.

10-10