attraction. The wick on an oil lamp can be lit because

the oil rises in the wick by capillary attraction. In each

of these examples, we have a liquid that moves into an

opening in a solid by the process called capillary

attraction. A basic rule of the process is that the distance

the liquid will be drawn into the opening in the solid

depends on the size of the opening in the solid. The

smaller the opening, the farther the liquid will be drawn

in.

This same capillary attraction causes the melted

filler metal used in silver brazing to be drawn into the

narrow clearance between the joining members.

Capillary attraction will not work unless the tiller metal

is in a fluid state and the size of the opening is quite

small (usually 0 to 0.012 depending on pipe or tube

size). Therefore, the application of heat and the use of

a very small clearance between joining members are

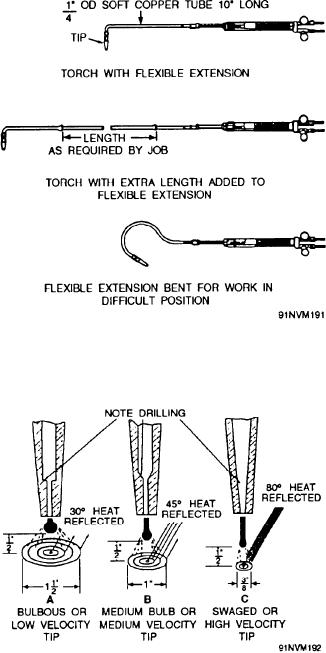

Figure 9-1.--Lightweight oxyacetylene torches with flexible

extension tubes.

essential to silver brazing. The heat is necessary to melt

the filler metal and to keep it molten. The small

clearance is necessary to allow capillary attraction to

draw the molten metal into the space between the joint

members.

You will often hear silver brazing called SILVER

SOLDERING or HARD SOLDERING. Silver brazing

is similar in many respects to soldering. The basic

distinction between a welding process and a soldering

process is that the metals or alloys used for a welding

process have melting points above 800F, while those

used for a true (or SOFT) soldering process have

melting points below 800F.

TORCHES

Figure 9-2.--Tip designs.

Silver brazing depends largely upon the operator's

manipulation of the torch to control the application of

heat. A lightweight torch with or without a flexible

The size of tip selected for the torch should be

extension tube (fig. 9-1) simplifies the silver brazing

determined by the size and type of work to be done. For

procedure and helps reduce operator fatigue. The

silver brazing sheet stock, for instance, you would

flexible extension tube is made of soft copper. It can be

ordinarily use size 4, 5, or 6. Table 9-1 may be used as

bent as needed to heat the surfaces to be joined.

a general guide.

Since one tip size cannot be used for making joints

on all thicknesses of metal, torches are provided with

SILVER BRAZING FILLER METALS

various sizes of tips. Tips are designed to heat a large

area and still allow little or no "bounce" (reflected heat).

Silver brazing filler metals are nonferrous metals or

Figure 9-2 shows the shapes of the flame at the ends of

alloys that have a melting temperature above 800F, but

different kinds of tips.

below the melting point of the base metal being joined.

The tip shown in view A of figure 9-2 has the lowest

You may have heard these silver brazing filler metals

velocity and heats the largest area. This tip should be

referred to as silver solder, hard solder, or brazing

alloys, but the correct term is silver brazing filler metals.

used in joining with silver alloys.

9-2