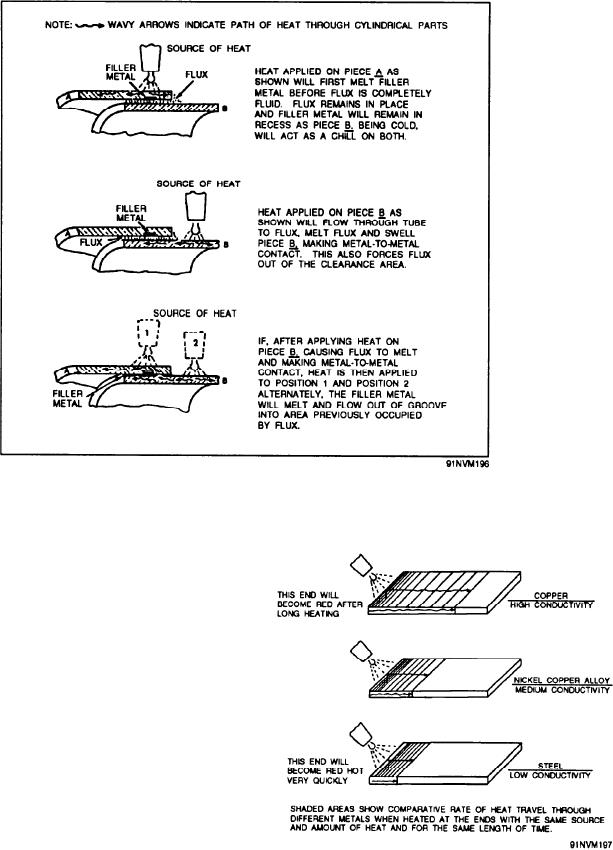

Figure 9-6.--Flow of flux and filler metal.

is carried away from it more slowly. The copper part,

on the other hand, conducts heat away from the brazing

area more rapidly than does the steel part. Therefore,

more heat is required to bring the copper part to the

brazing temperature.

Control of heat is one of the most difficult parts of

silver brazing. To do it properly, you must manipulate

the torch correctly, and you must remember the points

just discussed concerning the flow of heat through

metals. Basically, the problem of heat control in silver

brazing is one of bringing BOTH parts to the correct

temperature at the same time. If one piece is hot enough

but the other is not, the filler metal will flow onto the

hot piece, but it will not bond to the cooler piece.

If you have heavy and thin metal sections that must

Figure 9-7.--Relative rate of heat flow through copper,

be silver brazed, be careful to avoid overheating the thin

nickel-copper alloy, and steel.

part. A good example is the silver brazing of thin copper

tubing to a heavy cast fitting. If the same amount of heat

preheated for best brazing results. Preheating may be

were applied to the tubing as to the casting, the tubing

done with a forge, a furnace, or a welding torch.

would be overheated and probably burned. Therefore,

Joints must be clean and properly fitted for

most of the heat must be directed toward the heavier

satisfactory silver brazing. All parts to be brazed must

part. Frequently, heavy parts and large areas must be

be thoroughly cleaned to remove surface scale, oxide,

9-7