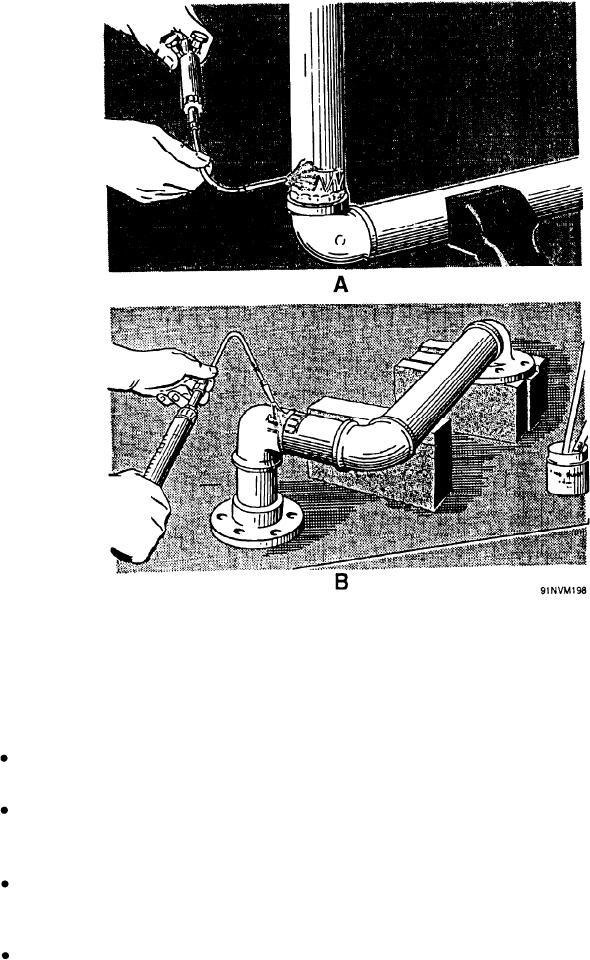

Figure 9-8.--Applying heat for silver brazing a tube and fitting.

Rust and corrosion should be removed by sanding,

oil, and grease. Any one or a combination of the

grinding, sandblasting, wire brushing, or filing. Oil and

following methods must be used for the cleaning of

grease should be removed with solutions of

scale and oxides or other foreign substances:

trichloroethylene or trisodium phosphate, not by heat.

Abrasive cloth, followed by wiping with an

The cleaned surfaces should not be handled un-

acetone-, alcohol-, or water-damp clean cloth.

necessarily. When parts have been cleaned and the

elapsed time before fluxing is more than 8 hours, the

Stainless steel wire brush, hand or rotary,

parts should be recleaned. Brazing alloy should be free

followed by wiping with an acetone-, alcohol-,

of all visible oxides, grease, oil, or other foreign

or waterdamp clean cloth.

substances when assembled or fed into the joint. Never

try to braze dirty metal.

Metallic stainless steel wool followed by wiping

Use a slightly carburizing flame to apply heat with

with an acetone-, alcohol-, or water-damp clean

the oxyacetylene torch for brazing with a silver-base

cloth.

filler metal. Select a torch tip to suit the type of work

Commercial cleaning solutions or degreasing

you are doing. Ordinarily a size 4, 5, or 6 tip is suitable

baths may be used when included in an approved

for silver brazing. Keep the inner cone of the flame from

one-fourth to one-half inch away from the metal. Play

brazing procedure or specification.

9-8