6. All circular measurements of a stub tooth gear,

STUB TOOTH GEARS

including the number of teeth and the pitch

Stub tooth gears are widely used throughout the

diameter, are the same as those of a spur gear.

automotive industry in transmissions because their

To find the pitch diameter, divide the number of

great strength enables them to transmit maximum

teeth (NT) by the diametral pitch (DP).

power. Cranes and rock crushers are examples of

type of gear has a 20-degree pressure angle and is short

and thick. A stub tooth gear compared to other gears has

7. To find the circular pitch (CP), divide ! (3.1416)

a shorter addendum (ADD). This results in a stronger

by the diametral pitch (DP).

tooth, but causes the gears to operate with more noise.

Stub tooth gears come in two forms. One form has

straight teeth, like spur gears. The other form has teeth

similar to those on helical gears. Gears with helically

8. To find the circular thickness (CT), divide

shaped teeth are used when smooth operation is

1.5708 by the diametral pitch (DP).

required.

The basic rule for spur, helical, and bevel gears, "for

every tooth on the gear, there is a circular pitch (CP) on

the pitch circle" also applies to stub tooth gearing

systems.

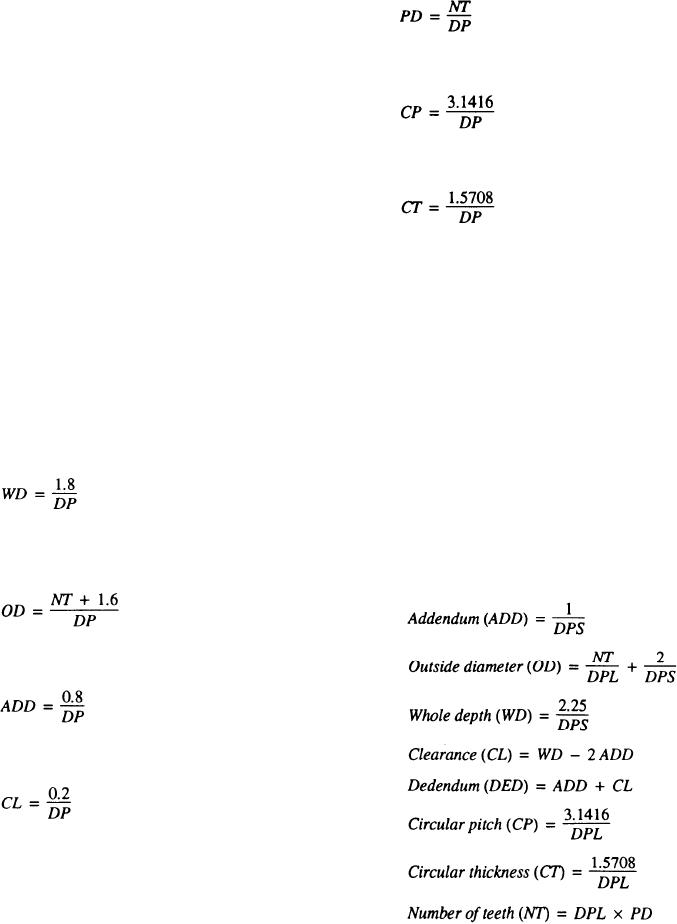

FELLOWS STUB TOOTH

We will discuss two stub tooth gearing systems: the

GEAR SYSTEM

American Standard System and the Fellows Stub Tooth

Gears System.

This system was introduced by the Fellows Stub

AMERICAN STANDARD SYSTEM

Tooth Gear Company. It uses a 20-degree pressure

This system bases tooth dimensions on specific

angle and is based on the use of two diametral pitches

formulas:

(DP). In the formulas we will use, the numerator (DPL)

is the circular measurement which consists of the pitch

1. The tooth depth or whole depth (WD) equals 1.8

diameter (PD) and the number of teeth (NT). The

divided by the diametral pitch (DP).

denominator (DPS) is the radial measurement.

There are eight standard pitches in this system.

They are 4/5, 5/7, 6/8, 7/9, 8/10, 9/11, 10/12, and 12/14.

2. To find the outside diameter (OD), add 1.6 to the

number of teeth and then divide by the diametral

The formulas for the basic dimensions are as

pitch (DP).

follows:

1.

3. To find the addendum (ADD), divide 0.8 by the

2.

diametral pitch (DP).

3.

4. To find the clearance (CL), divide 0.2 by the

4.

diametral pitch (DP).

5.

6.

5. When the addendum (ADD) is added to the

clearance (CL) the result is the dedendum

7.

(DED).

DED = ADD + CL

8.

14-27